- TopSolid

- Products & Industries

- All CAD, CAM & PDM software - TopSolid

- TopSolid'Inspection

Ballooning and dimension control

- Optimize your quality controls

- OCR and dimension ballooning

- Custom editions

- Shopfloor data entry interface

- Dematerialization and traceability

- Analysis and capability

- Features

Optimize your quality controls

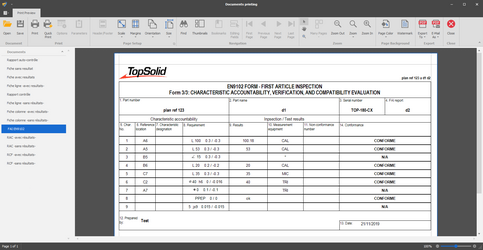

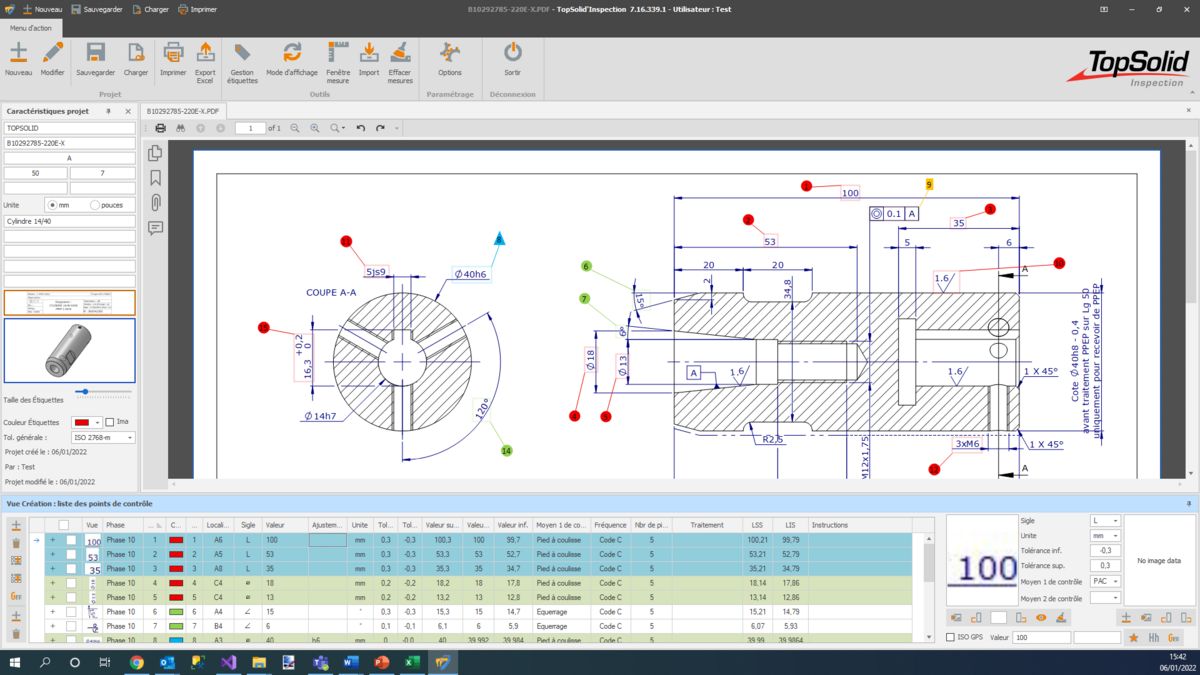

TopSolid'Inspection is a software package that supports the quality department of production companies, notably allowing the creation of inspection reports.

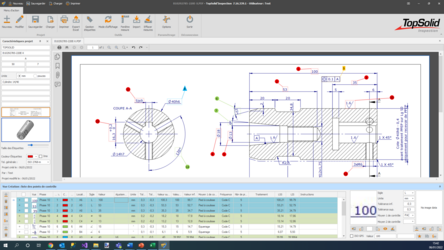

Reading the part drawing is at the heart of the part control quality process. TopSolid'Inspection works directly on the 2D drawing to retrieve the value of the dimensions to be measured, which makes it possible to automatically launch processes that were initially very time-consuming.

The two main features of TopSolid'Inspection are:

- Recovering dimension values by ballooning the drawing in order to build a document listing the control points to be noted on the part.

- Feedback of measurements made on the shopfloor via a simplified data entry interface.

Saving time, limiting errors and traceability are the objectives.

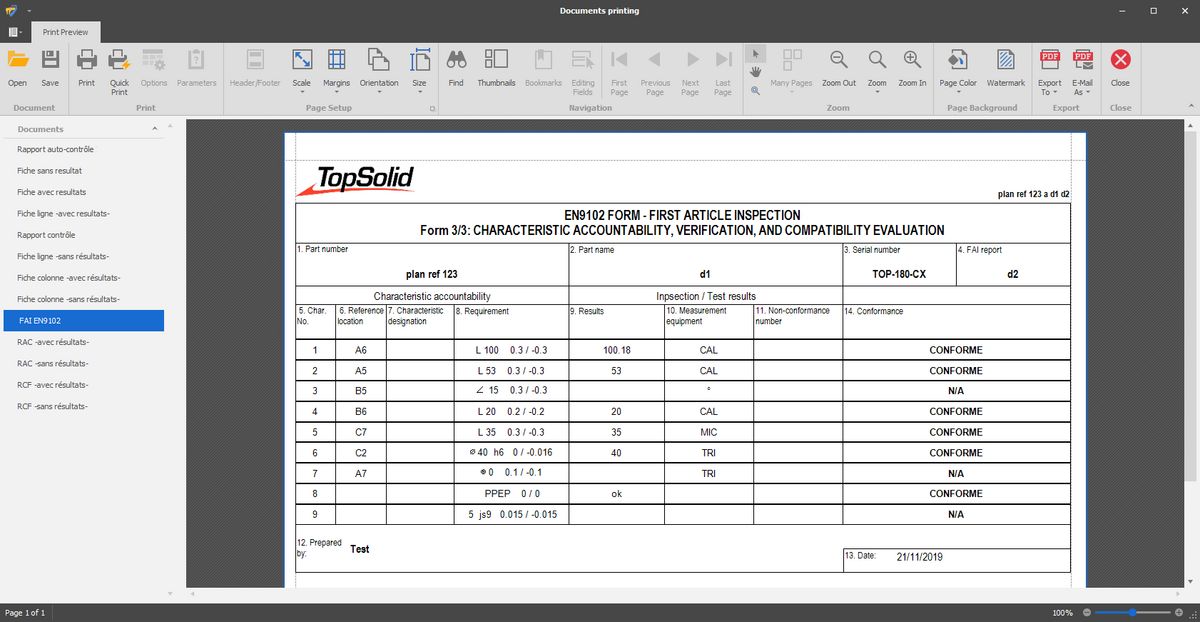

OCR and dimension ballooning

The part drawing in image, scan, TIFF, PDF, DXF and DWG format is integrated into the application at the inspection project level where the characteristics specific to manufacturing are defined (customer, order, production order, quantity of parts produced, serial numbers, etc.).

The control point list is created by ballooning the dimensions directly on the drawing of the part. The value of the dimension is retrieved via a character recognition, this allows an automatic supply of tolerances (according to the general tolerance or the fitting), control frequency, location in the drawing, etc.

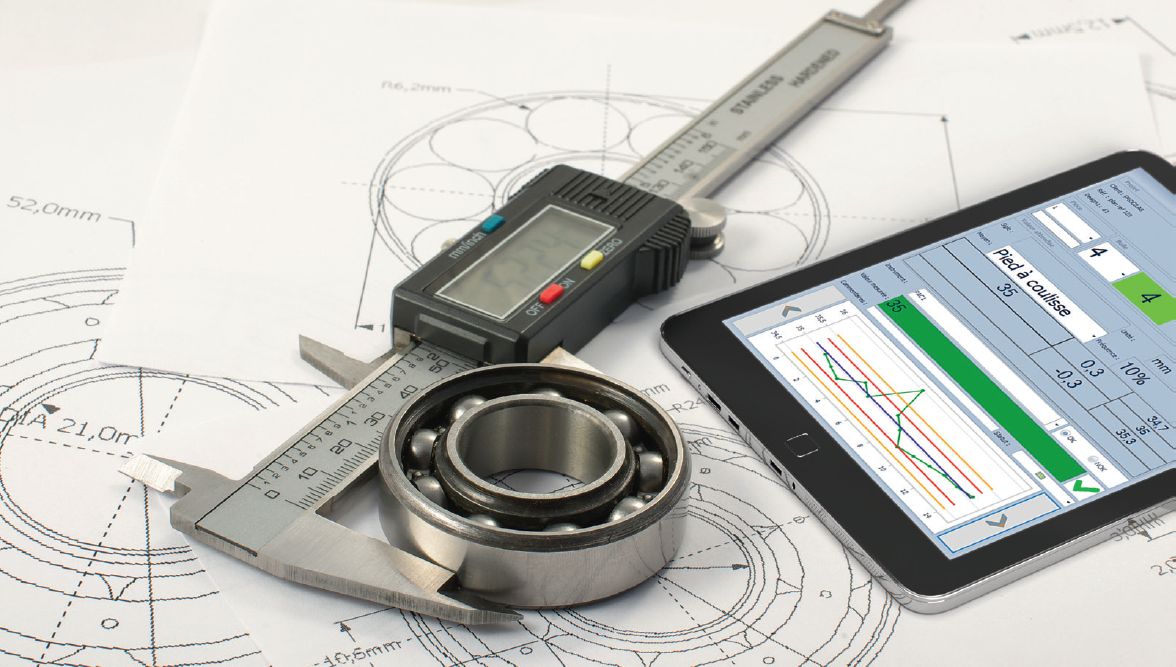

Shopfloor data entry interface

The software or its simplified version is portable in the workshop on a PC or Windows tablet for the measurement feedback.

Measurements can be entered manually using the keyboard or via a connected control mean.

- Zero paper

- Windows tablet interface

- Compatible with connected control means

- Management of monitoring limits

- Management of measuring instrument

- Dynamic control chart

Dematerialization and traceability

Monitoring plan information and measurement session results are centralized in a single location, easily integrated into your management system (CAPM, ERP).

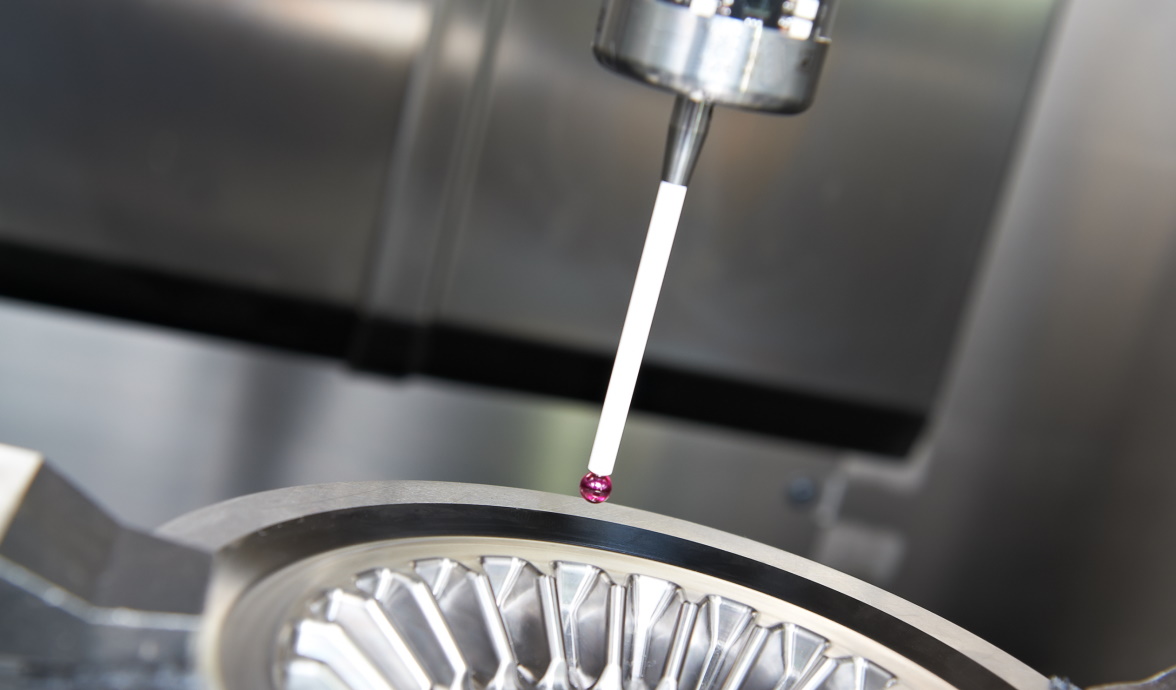

Measurements can be taken from workshop feedback via the tablet interface, or retrieved from a third-party software report (three-dimensional, connected means). Data can be queried, enabling traceability of measurements, controllers, measuring instruments used, etc.

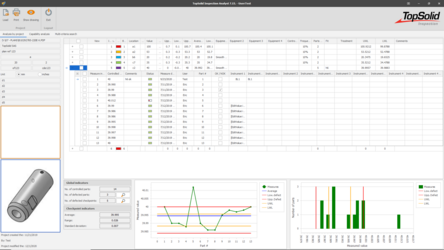

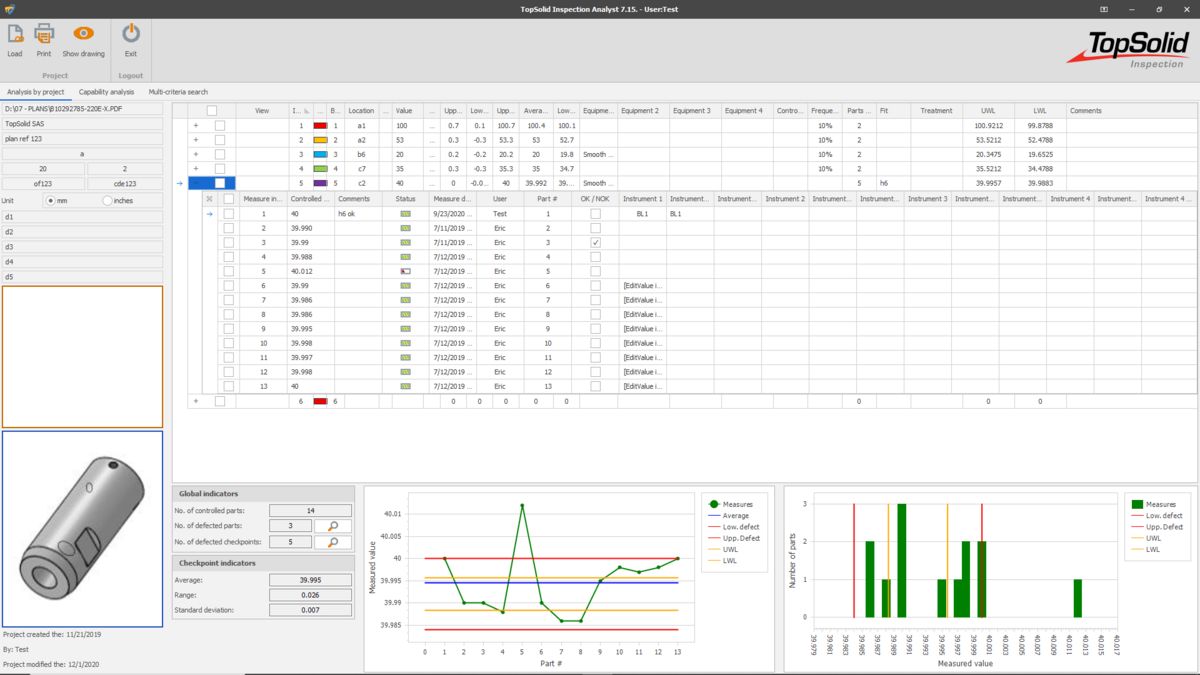

Analysis and capability

An interface for analyzing the results allows you to obtain indicators and control charts for a project or a set of sampling projects:

- Measurements and attributes control chart

- Capability study, Cp, Cpk

A multi-criteria search tool allows you to find projects, control points, control means according to the selection criteria (dates, customer, control mean, etc.).

Features

- Automatic metric/inch conversion

- Management of parts serial numbers

- Color, size, orientation, balloon ordering

- Database of general tolerances and fittings

- Management of control means

- Management of treatment thicknesses

- User traceability with configurable access rights

- Phase management

- Import of results from an Excel MMT report

Discover software

TopSolid'Inspection at a glance

TopSolid'Inspection videos

For more information

The TopSolid 30 Day Trial is available for free and includes the full version of TopSolid and FREE tutorials to help you get started.

TopSolid'Viewer allows you to view and share any TopSolid document (design, drawing, machining, kinematics etc) without the need for a TopSolid license. TopSolid'Viewer is free of charge and available in versions 6 and 7.

TopSolid'Store offers free downloadable content around TopSolid.

TopSolid'Inspection documentation

Need more information