Additive manufacturing software using the patented Stratoconception® process from CIRTES to manufacture your parts in 3D slices using any material plate

- Additive manufacturing module integrated in the CAD environment

- Breaking down a part into slices

- Integrated assembly features

- Optimization of material consumption

- Automatic generation of tool paths

- Different ways of cutting using micro-milling

- Decision support through numerous libraries

- Unique patented process

Additive manufacturing module integrated in the CAD environment

- Additive manufacturing module integrated in the TopSolid suite.

- Use of a 100% native model (designed or imported in TopSolid).

- Removal of the STL mesh (a standard in additive manufacturing).

- Complete interoperability with other TopSolid software: TopSolid'Design, TopSolid'Cam, etc.

- Changes made to the model result in the update of the slice breakdown, and of the associated machining operations.

- Intuitive to use thanks to the standards of the TopSolid environment.

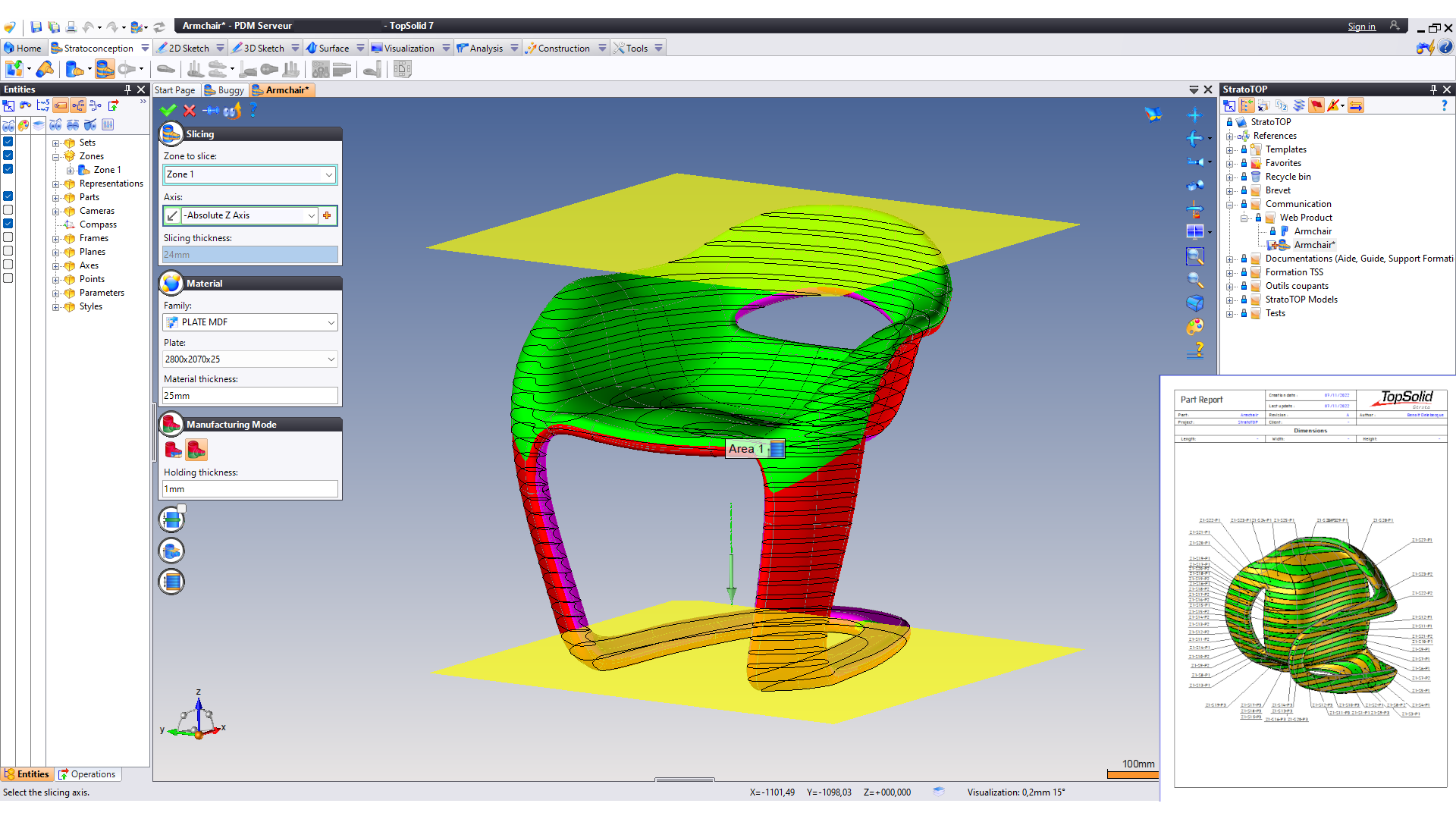

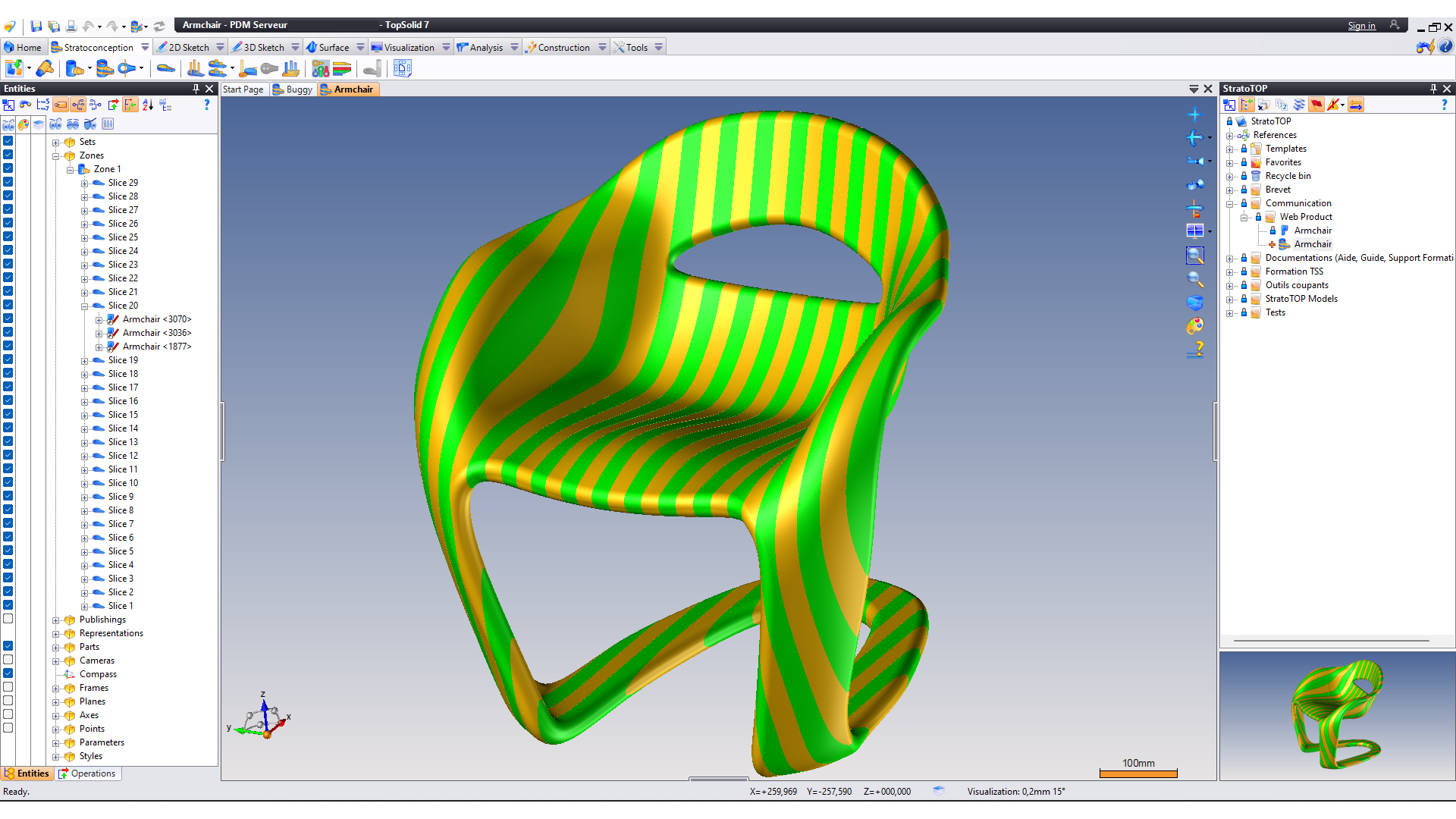

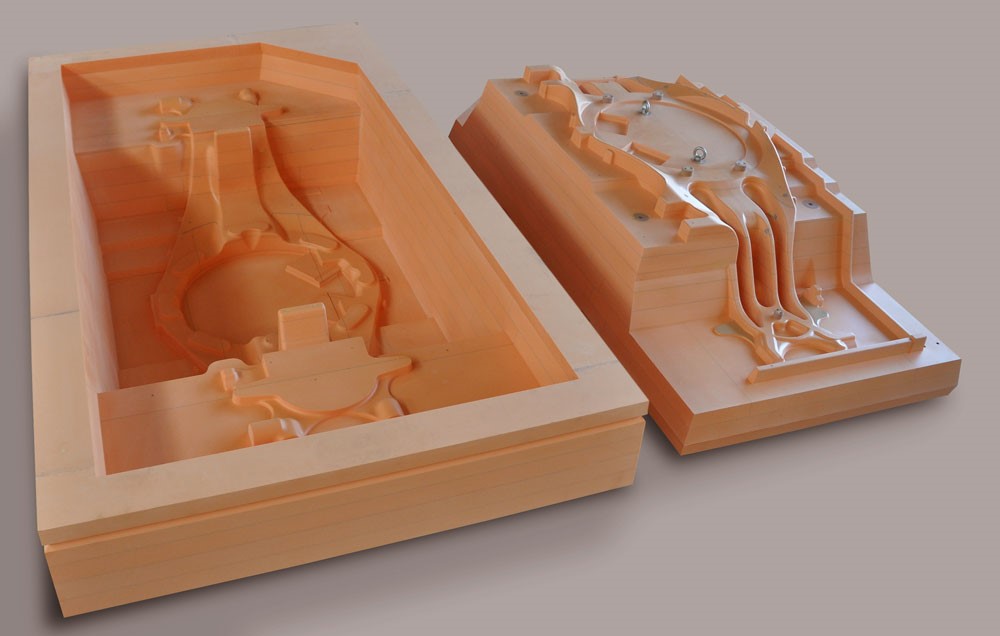

Breaking down a part into slices

- Slicing design guided by a succession of steps.

- Management of a part in several areas that can be produced with different parameters (axis, slice thickness and material).

- Slicing according to a defined thickness and axis.

- Advanced slicing feature thanks to additional planes and the choice of slice distribution.

- Breaking down slices to produce parts out of the machine gauge.

- Slice hollowing to reduce the weight of a large part or tooling, or to optimize the quantity of material used.

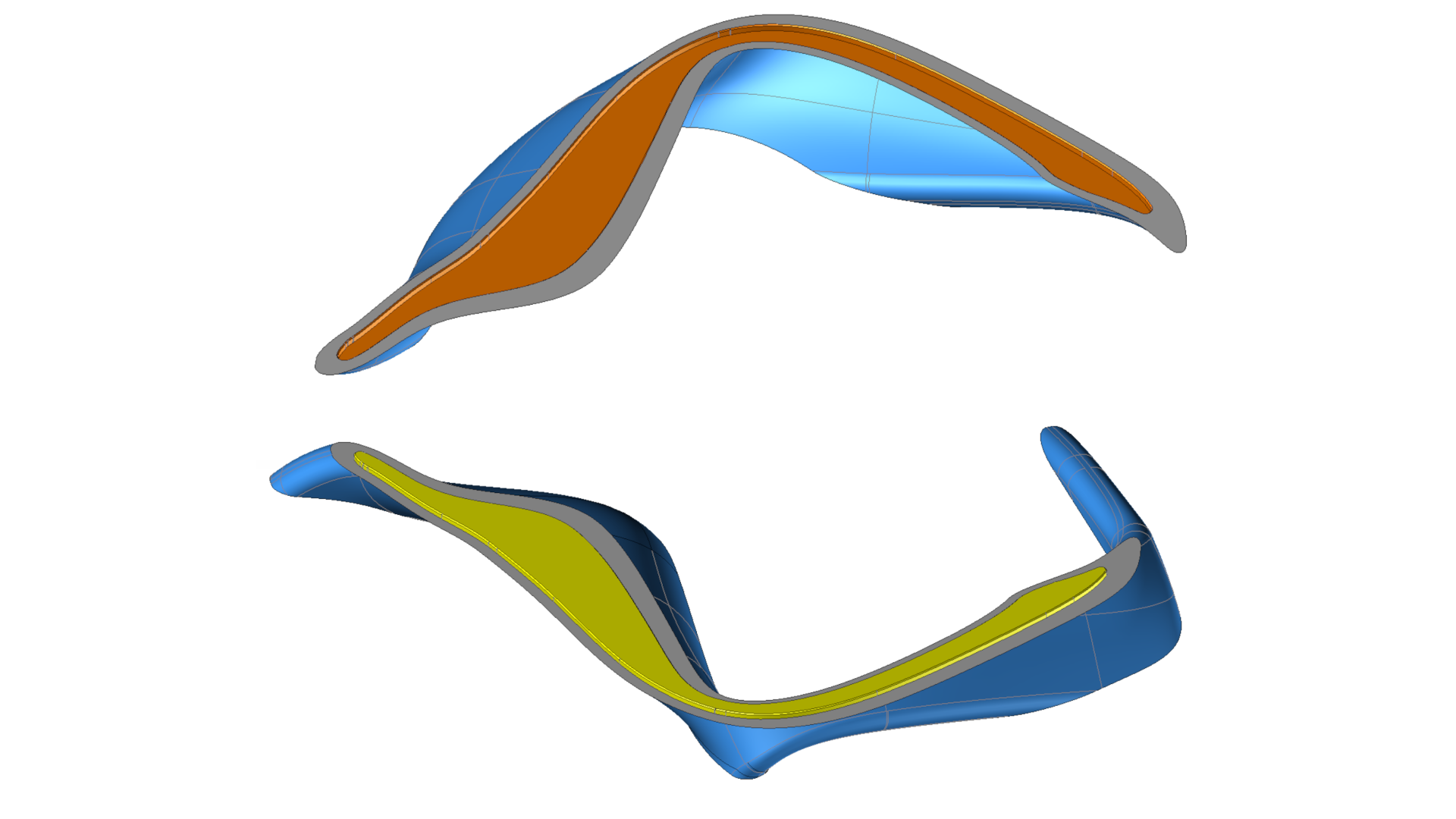

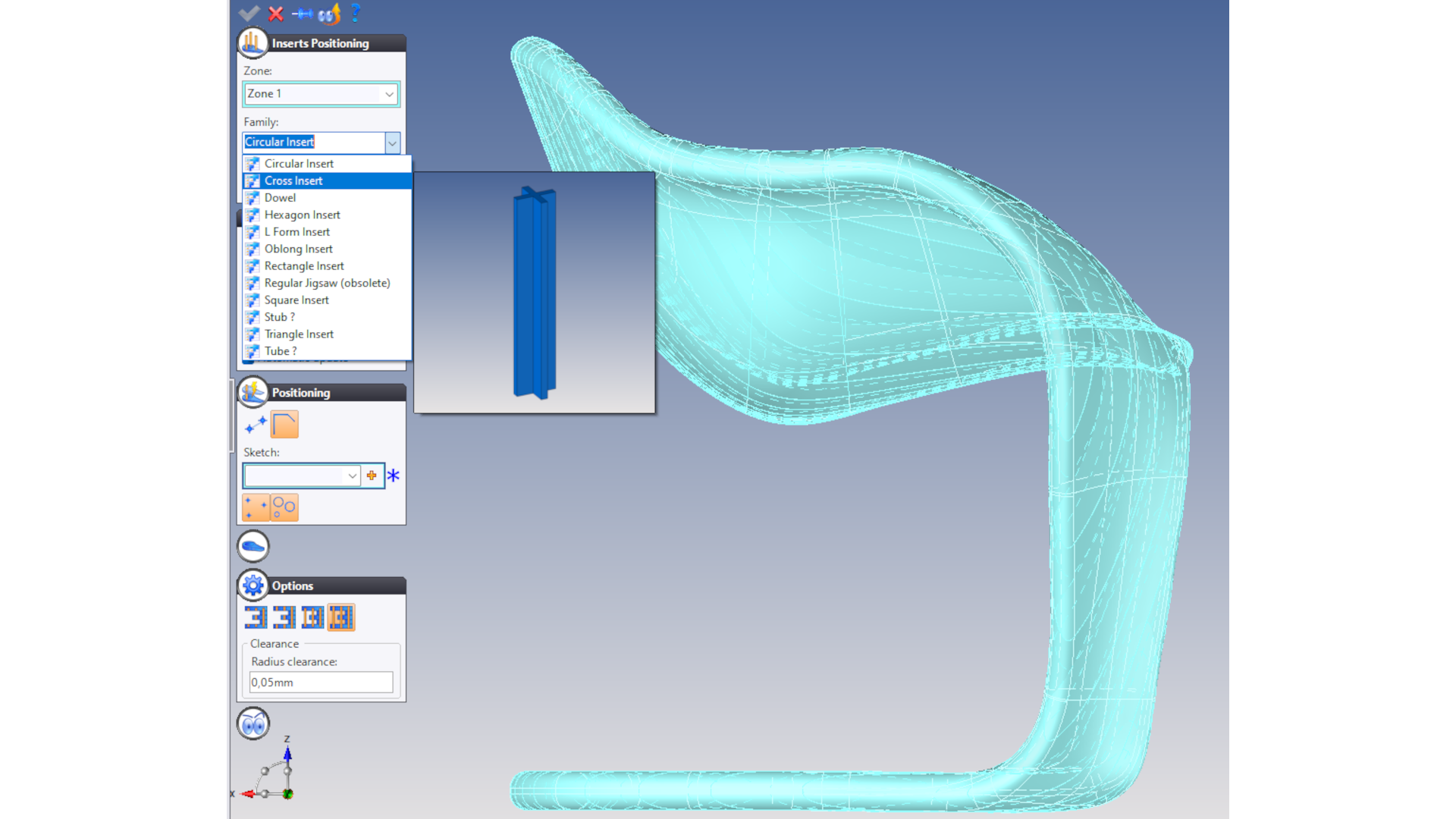

Integrated assembly features

- Adding assembly features to the slice design.

- A range of assembly features:

- Inserts: inserts (standard or manufactured components) which allow the positioning of the slices in relation to each other.

- Jointing with pins and housings: consisting of a male part (the pin) and of a corresponding female part (the housing), integral parts of the slice and machined at the same time as the slice.

- Bridges: assembly elements placed outside of the part and linked to it by a scaffold, for thin or transparent parts.

- Complete nesting: complete nesting of the upper slice in the lower slice.

- Assembly keys: elements for the positioning and maintenance of the disintegrated parts. They are either attached parts, or integrated into the slices.

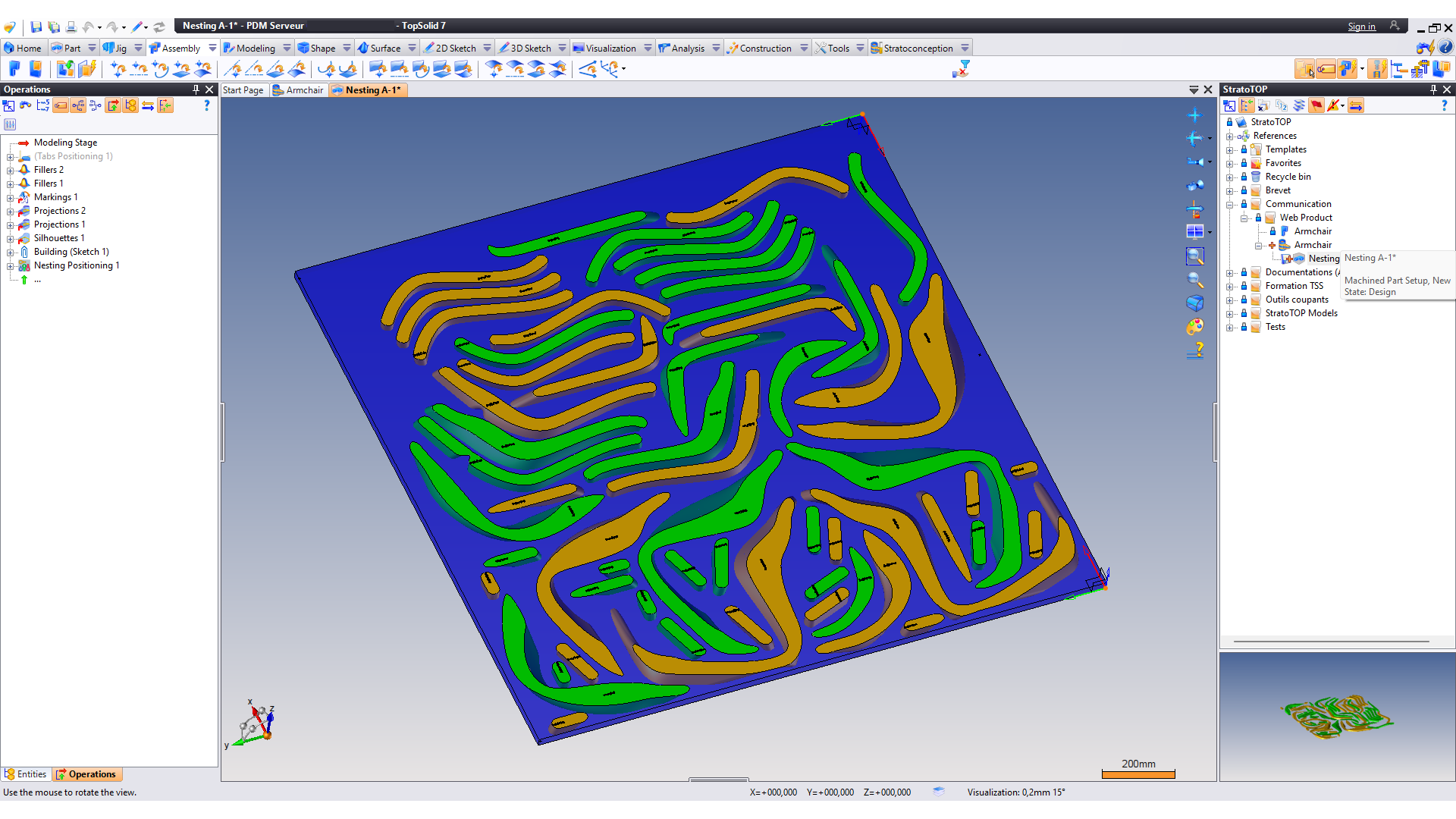

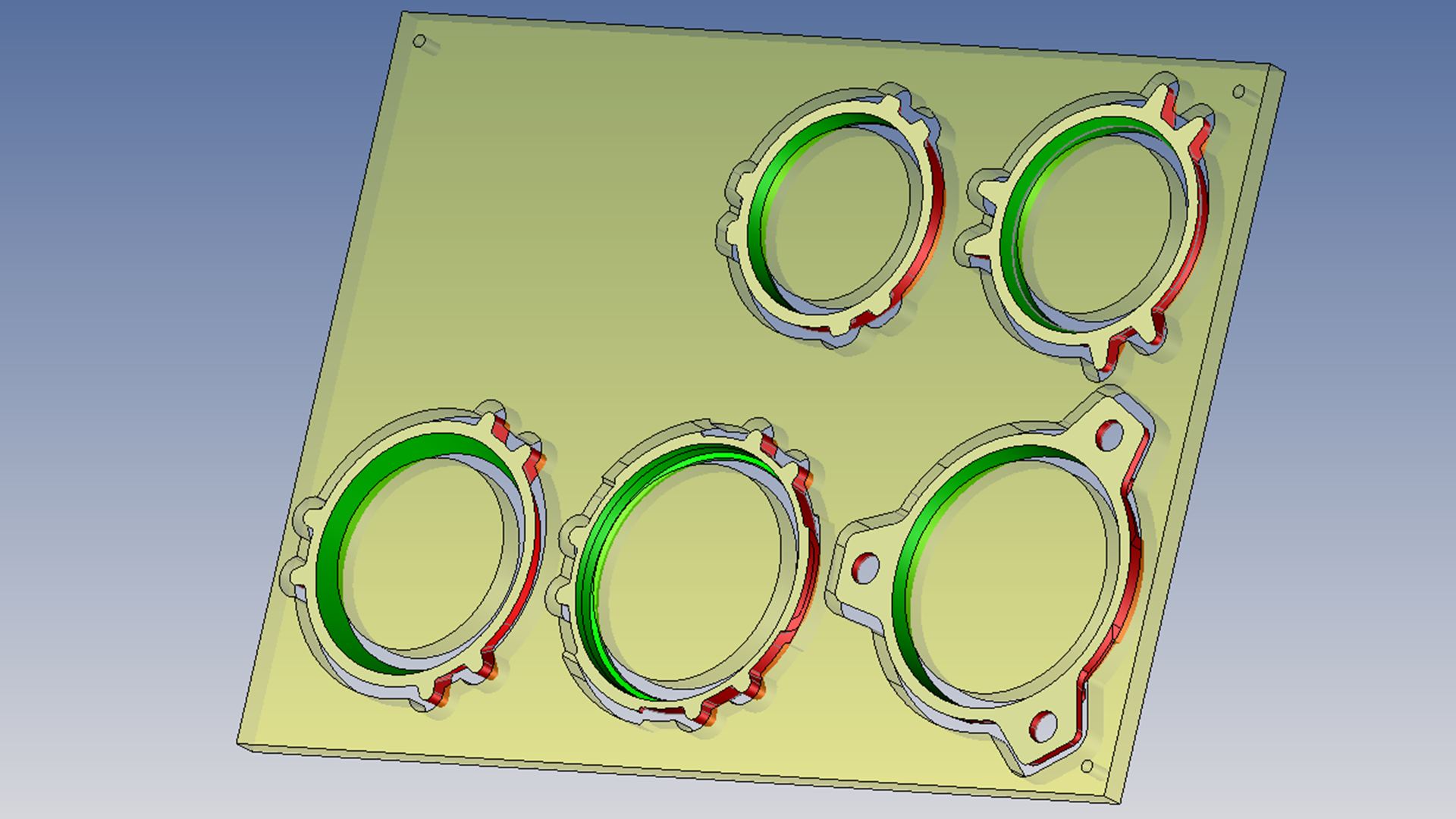

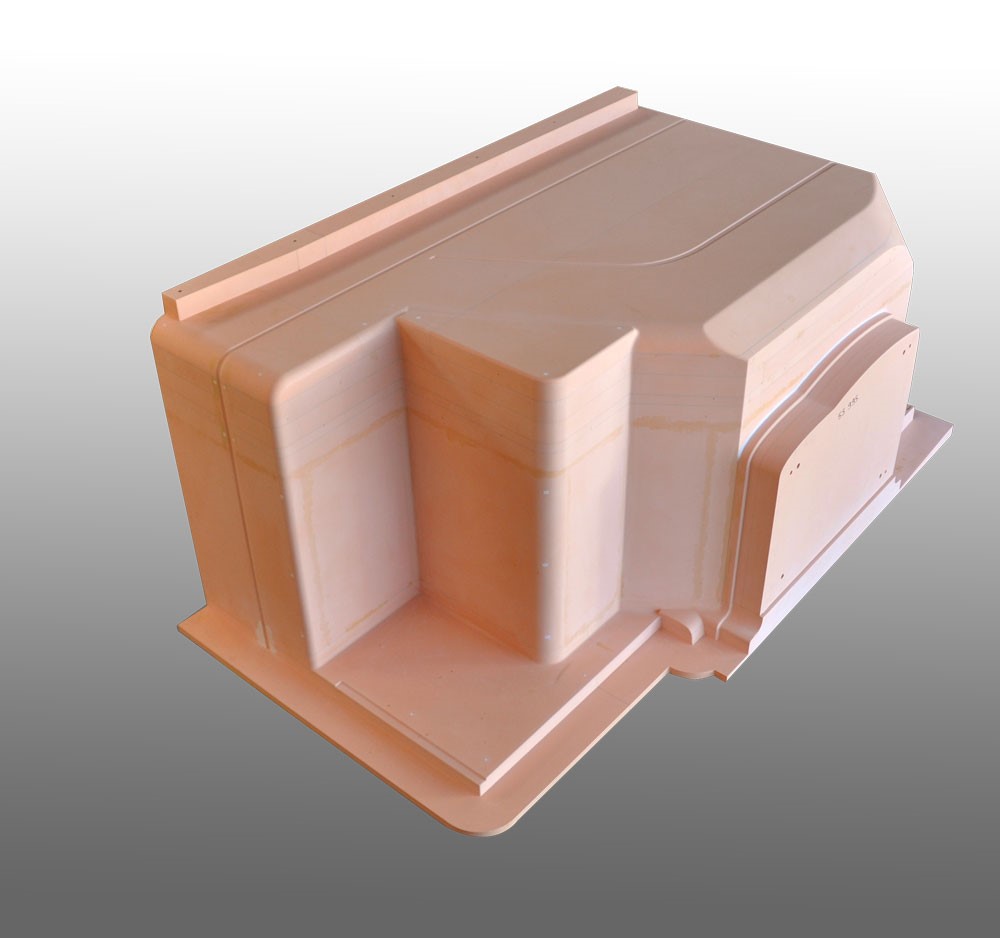

Optimization of material consumption

- Nesting optimization to distribute all the slices (or parts of slices) in raw material plates, by optimizing the amount of material needed.

- Automatic selection of the slice machining direction based on the slice geometry.

- Placing calibrated pins to position the plate during its turning.

- Identifying the slices in the nesting by an engraving.

- Breaking down slices into parts to use small plates, or to save material for curved slices.

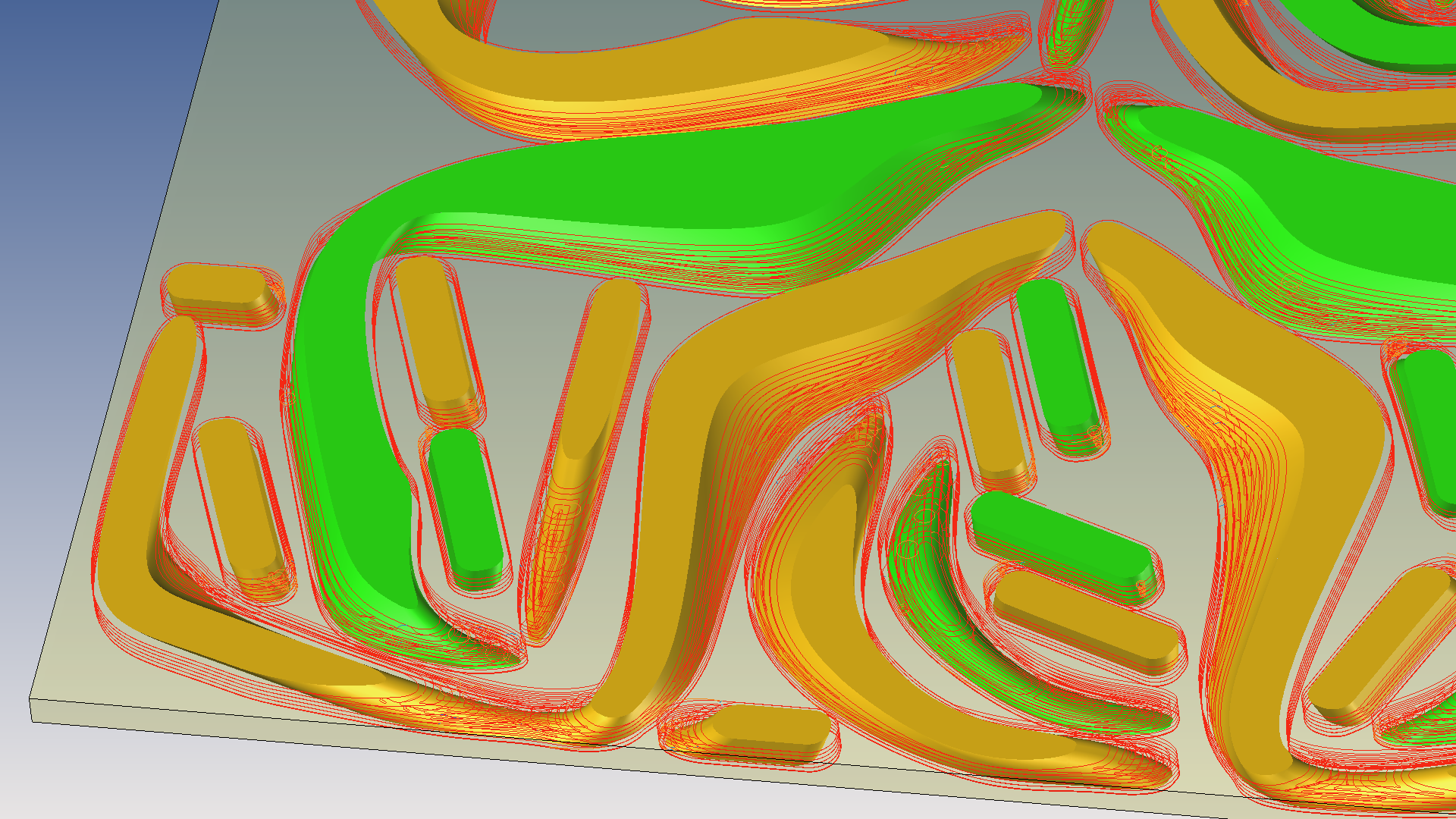

Automatic generation of tool paths

- TopSolid'Strato automatically generates machining operations to produce the slices and assembly elements, according to the available manufacturing methods.

- All the required operations are performed:

- Slice leveling, insert drilling, pin machining, slice roughing and finishing, marking of the slice number.

- Optimized slice finishing strategy using a mix of contouring and sweeping.

- Differentiated machining methods to allow for field adaptations.

Different ways of cutting using micro-milling

- Slice machining either in a nesting, or by stacking, or by combining two modes.

- Double-sided nesting machining mode: slice nesting machining of the two sides by turning the plate to reach the undercut areas.

- Stacking machining allowing successive machining, slice by slice, within the machine.

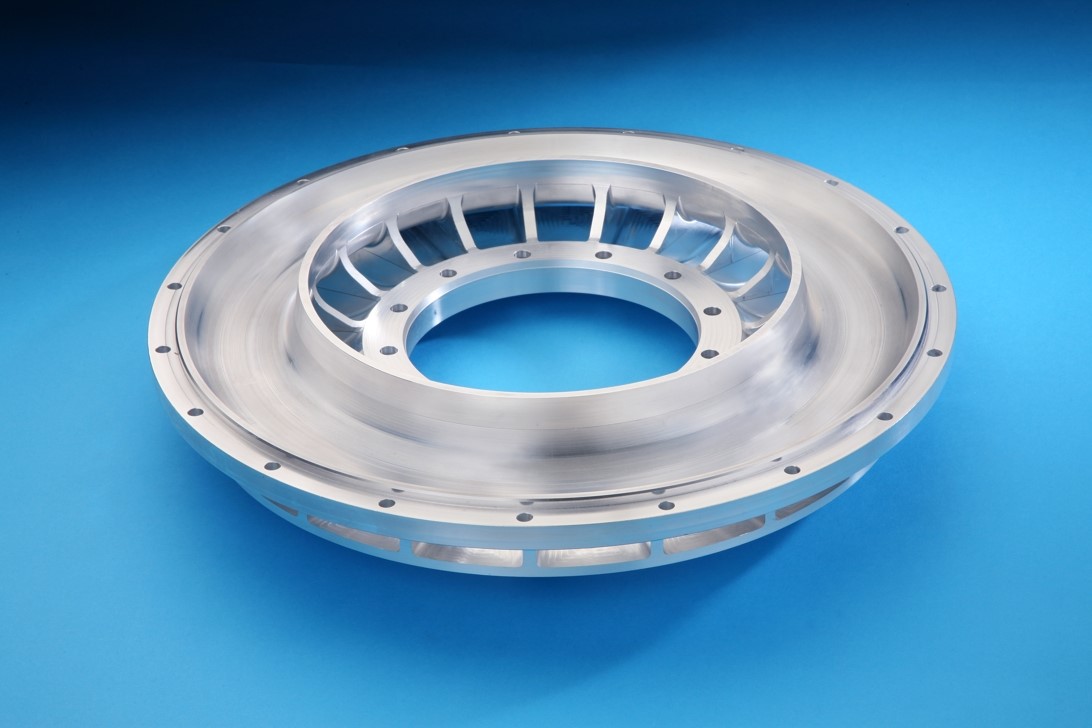

Unique patented process

- Various fields of application: models, templates, toolings, direct parts, etc.

- Variety of material plates: machinable resins, woods, polymers, metals, etc.

- Easy supply: stock of standard material plates (no raw material required).

- Very large parts (up to several meters).

- Economical: optimization of the material used (additive process), low material cost, low power consumption.

- Simplicity: systematic, whatever the geometry.

- Simple CNC: only 3 axes to produce complex geometries with small micro-milling tools (finishing).

- A French process, patented and developed by CIRTES, R&D center in additive manufacturing with over 30 years of experience (www.cirtes.com).

Discover software

TopSolid'Strato at a glance

For more information

The TopSolid'Strato module developed by CIRTES offers TopSolid 7 users the possibility of producing very large parts. The Stratoconception® Additive Manufacturing process breaks down a part into slices for its manufacture in plate materials.

The TopSolid 30 Day Trial is available for free and includes the full version of TopSolid and FREE tutorials to help you get started.

TopSolid'Store offers free downloadable content around TopSolid.

TopSolid'Strato documentation

Need more information