Convert raw statistics into a competitive advantage: optimize your resource allocation and fuel peak productivity across your entire manufacturing operation.

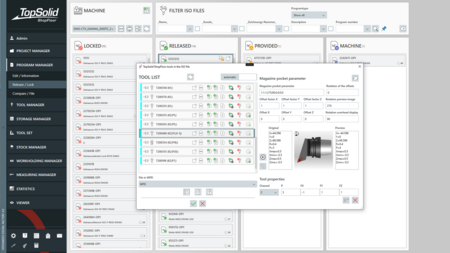

Unlock Peak Efficiency Through Streamlined Turret Configuration

Unshackle your machining strategies from rigid machine specifications.

Customize your turret configuration directly within each individual ISO file. This newfound operational autonomy allows you to adapt tooling setups precisely to the unique demands of every machining context, ensuring perfect alignment between virtual CAM programming and shop-floor execution. By removing intermediate configuration steps, you achieve a workflow where responsiveness and reliability are perfectly synchronized.

- Context-driven configuration: Specify turret parameters at the ISO level to match the exact requirements of every cycle-specific operation.

- Streamlined workflow: Eliminate redundant global machine reconfigurations, reducing setup times and minimizing the risk of costly programming errors.

Work faster, set up smarter, and execute with greater precision—maximum productivity, project after project.

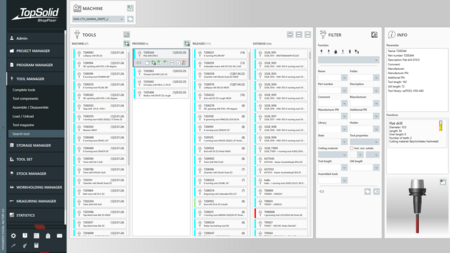

Smart Item Display: Total Control Over What Matters Most

Align your interface with your priorities.

Take command of your workspace with the new dynamic expand and collapse functionality. You decide the exact level of detail displayed at any given moment, allowing you to surface only the information relevant to your current task. By filtering out non-essential data, you transform a dense interface into a streamlined, high-performance environment.

- Adaptive visibility: Expand items to access detailed information when needed, or collapse them to maintain a clean, distraction-free workspace.

- Improved efficiency: Eliminate visual noise, accelerate navigation, and maintain concentration throughout complex workflows.

A clearer interface for sharper focus: transform complexity into clarity and work with unprecedented efficiency.

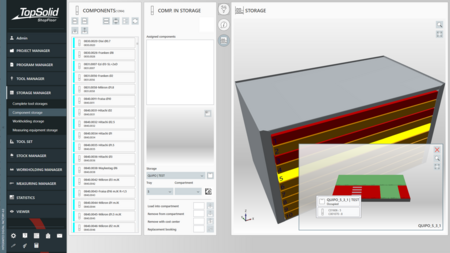

Maximize Workshop Capacity with Free-Compartment Visualization

Assess your storage availability at a glance with intelligent color-coding.

Experience a new level of organizational clarity. Drawers and compartments are now dynamically color-coded based on their real-time status: occupied, free, or partially occupied. This intuitive visual feedback gives you immediate insight into available space, eliminating guesswork and manual inventory checks.

- Instant capacity intelligence: Identify free storage zones immediately through a high-contrast, intuitive color-mapping system.

- Optimized space utilization: Maximize every square centimeter of your workshop by visualizing partial occupancy and consolidating inventory.

- Frictionless logistics: Streamline the storage process and reduce search times with at-a-glance status updates.

Accelerate decision-making and sharpen your organizational clarity for a leaner, more efficient workshop.

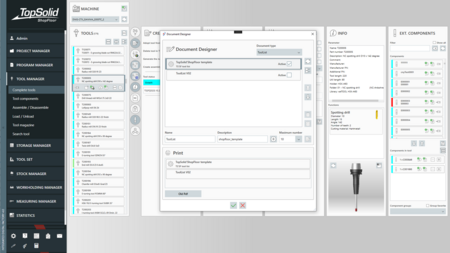

Design Professional Reports with the Integrated Document Designer

Tailor every document to your exact technical requirements and corporate identity

Take full control of your documentation with the integrated Stimulsoft Designer. This powerful engine allows you to create and personalize document templates directly within the system. Whether for individual projects or enterprise-wide standardization, every user can now design, save, and manage bespoke templates that ensure professional consistency across all technical outputs.

- Bespoke template architecture: Build advanced layouts for reports, tool and component lists, and technical documents within an intuitive, integrated design environment.

- Operational autonomy: Create and manage personal or shared templates independently, eliminating the need for external tools.

- Output standardization: Guarantee a consistent brand identity by deploying unified templates across your entire organization.

Streamline your reporting workflows and ensure every document reflects your standards.

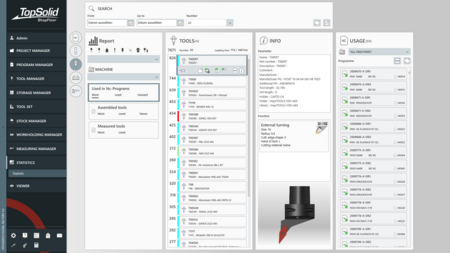

Gain Deeper Insights with the New Statistics Module

Turn operational data into a strategic roadmap for resource optimization.

The new Statistics module delivers a high-precision, data-driven view of your production environment. Analyze ISO files, tool components, complete tools, workholdings, and measuring equipment through detailed usage metrics. Instantly pinpoint high-performance assets, identify underutilized components, and detect obsolete inventory—all from a single, consolidated solution.

- Comprehensive usage analysis: Monitor real usage frequency across ISO files, tooling, workholdings, and measuring devices to reveal true production patterns.

- Resource optimization: Identify redundant or underperforming components to lean out your inventory and reduce operational costs.

- Informed decision-making: Drive tooling investments, replacements, and maintenance schedules using factual lifecycle data—not assumptions.