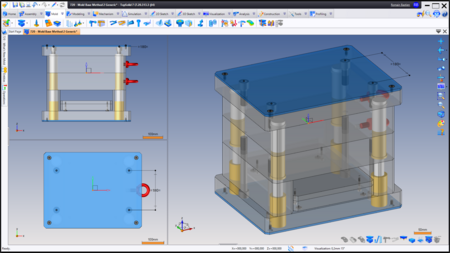

Customize Mold Base Insertion with Methods

Embed your standards at the core of your design process.

TopSolid’Mold 2026 revolutionizes mold base insertion by harnessing the power of methods. You are no longer restricted to generic placement routines; instead, you define your own insertion and positioning logic, ensuring every project aligns perfectly with your unique technical expertise.

- Bespoke automation: Apply proprietary business rules for intelligent, fully automated mold base positioning.

- Guaranteed standardization: Ensure tooling consistency by enforcing your design standards across every new project.

- Exponential efficiency: Eliminate manual adjustments and reclaim valuable engineering time during design phases.

Don’t just place mold bases. Deploy your methodology.

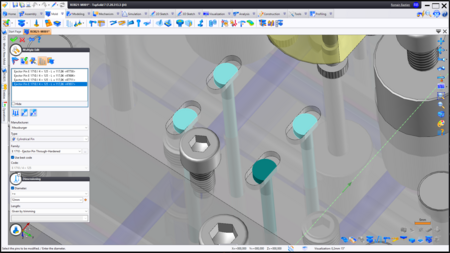

Increase Productivity with Multi-Editing of Ejector Pins

Optimize design revisions with unprecedented agility.

A new dedicated command now allows you to simultaneously modify an entire set of ejector pins—including diameter, family, or attributes. Say goodbye to time-consuming, one-by-one interventions: manage your entire ejection system in a single operation with absolute consistency.

- Rapid execution: Apply global changes in seconds, even on the most complex molds.

- Enhanced reliability: Eliminate the risk of omissions or manual errors by instantly synchronizing component properties.

- Design ergonomics: Remove repetitive tasks to focus on the high-value technical optimization of your projects.

Stop fighting repetitive changes. Drive your ejection systems with surgical precision.

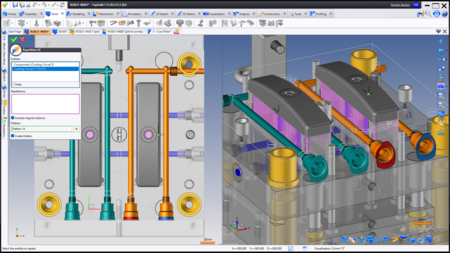

Automate Cooling Circuits with Intelligent Pattern Repetition

Accelerate the design of your most demanding thermal management systems.

Cooling circuit management has evolved: create parameterized patterns that automatically re-apply all associated processes. Impacted targets are recalculated in real time, guaranteeing total geometric accuracy without any manual intervention.

- Geometric integrity: Eliminate errors through the automatic recalculation of targets and operations.

- Modification agility: Adjust parameters once and let the system update the entire circuit instantaneously.

Don't design circuits one by one. Inject intelligence into your cooling networks.

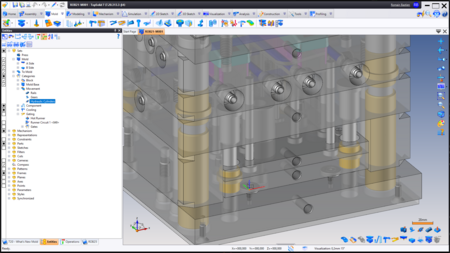

Tailor Your Workspace with Custom Sets

Work within an interface fully aligned with your engineering logic.

The user interface now features a fully customizable Sets Access Bar. Organize and display component groups according to your own standards or mold typology (hot runner systems, lifters, cylinders, gears, etc.).

- Immediate access to essentials: Isolate key information in one click with a toolbar structured for your specific needs.

- Industry-specific ergonomics: Work in a visual environment that reflects your design methods and the complexity of your tooling.

- Streamlined focus: Reduce cognitive load by displaying only the data relevant to each phase of the project.

Your interface adapts to your workflow. Your productivity follows naturally.

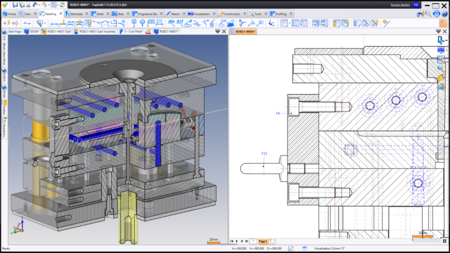

Streamline Drafting via Direct 3D Section Extraction

Bridge the gap between the 3D model and its documentation.

Sections defined directly within your 3D mold are now natively exploitable for 2D drafting. Your views are generated instantly—without re-entry or data duplication—ensuring total continuity between design and the shop floor.

- Instant view generation: Create technical drawings in record time by leveraging the intelligence of the 3D model.

- Full associativity: Ensure perfect synchronization between design and documentation via a dynamic link.

- Operational excellence: Eliminate redundant tasks to focus on the added value of your engineering layouts.

Accelerate and secure your project documentation—without breaking the workflow.