18 oktober 2023

Stemming from Fermetures Ventoises, a company founded in 1886 in the small town of Arnières-sur-Iton, France, Métallerie Ventoise specializes in the design, manufacturing, and installation of steel metalwork. To support its expansion in the Eure department and boost its productivity, the company’s teams have been using TopSolid'Steel since 2018. Here are the key points that led to this successful partnership.

Métallerie Ventoise: historical expertise and modern practices

Métallerie Ventoise is the result of many changes. Formerly known as Fermetures Ventoises acier - a company founded in 1886 and acquired by the YESKA group in 2002 - Métallerie Ventoise took over the entire steel metalwork business of the original company in early 2023. In addition to a change of name and logo, the creation of this new entity also resulted in a move to Incarville, in premises over 2000m² wide, as well as in the implementation of a new industrial tool. Indeed, with a €5.5 million turnover by the end of 2022, the company needed a new space to fully deploy its activity.

Comprehensive technical service

Métallerie Ventoise specializes in the design, manufacturing, and on-site installation of metalwork, primarily for multifamily housing in the Paris and Normandy regions. The company's teams work closely together to provide customers with a quality service that includes:

- Product design carried out by an approved design office;

- Products manufactured by 10 metal welders;

- Installation of the products by 4 different teams of professionals.

An environmental approach

This expert work is also part of a sustainable development approach, with particular attention paid to the manufacturing location of the products: "Products are made in France, in our workshop in Incarville, using local supplies and a network of local subcontractors," explains Delphine Bauche, head of the Métallerie Ventoise's Design Office; an excellent way to combine performance and environmental responsibility.

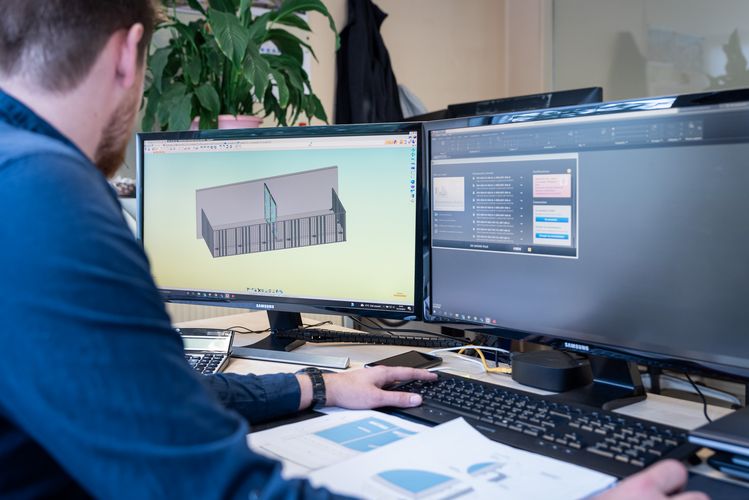

TopSolid'Steel: the answer to a technical need

The Métallerie Ventoise's Design Office worked with the AutoCAD software to design its products’ parts for several years. However, the impossibility to perform 3D design motivated a software change. That is why the company launched a market study in 2018 to identify the limitations and strengths of different CAD software packages and requested technical presentations from each of the publishers. The focus was of course on the ability to perform 3D design, but also on the software's ease-of-use and the technical support that would be provided for its implementation and ongoing development.

Considering all these criteria, Métallerie Ventoise finally chose the TopSolid'Steel solution to support its projects.

"TopSolid was chosen for its ease-of-use and ergonomics. We thought the technical support to be responsive and efficient. The ongoing development of the software was also a key factor." Delphine Bauche, Design Office Manager at Métallerie Ventoise

And while it took a little over a year to switch entirely from AutoCAD 2D design to TopSolid 3D design, the implementation of the software was facilitated by several training sessions:

"The implementation of the software involved basic training for all draftsmen, followed by specific training sessions with experts coming to our premises for specific needs," explains Delphine Bauche.

TopSolid'Steel, a performance engine for Métallerie Ventoise

After 5 years of using TopSolid'Steel, the teams at Métallerie Ventoise are still pleased with their choice in terms of technical features and human support.

Essential features

Overall, the Design Office was impressed by TopSolid'Steel's functionalities and particularly appreciated the following features:

- The parts parameterization, allowing a precise configuration of the needed parts;

- The bills of materials generation, providing the length, description and quantity of the parts used;

- The extruded bar function, allowing to create a library of used parts and to reuse existing draftings;

- The multiple draftings command, automating the layout of all modules and speeding up production in the workshop.

Efficient and attentive contacts

Métallerie Ventoise also appreciates the human skills of the TOPSOLID teams. Delphine Bauche particularly emphasizes the "proximity" and "responsiveness" of the teams, who provide a real added value to the software implementation: "We called the hotline regularly. We have had a very good business and technical relationship", she declares.

Multiple benefits

With these two aspects, the TopSolid'Steel solution has helped Métallerie Ventoise enhance its performances on various levels:

• Part throughput and module standardization have simplified industrialization for the purchasing department and workshop.

• Drawings with 3D view have enabled installation teams to better visualize interfaces with other trades and helped customers project themselves more easily.

• The software's parameterization and automation have enabled designers to improve their speed and reliability during the manufacturing.

Time and precision savings, high-level interface management, collaborative approach... Since its implementation in 2018, TopSolid'Steel has proven itself and supported Métallerie Ventoise in more than 50 projects. "TopSolid is a complete and efficient software package with high-quality support," concludes Delphine Bauche, for whom TopSolid is now an integral part of Métallerie Ventoise's tools.

Meer informatie nodig

EEN VRAAG OVER ONZE PRODUCTEN OF OPLOSSINGEN?

Vind uw dichtstbijzijnde verkooppuntContacteer onsVraag een offerte aan