28 February 2011

The road to success with new means. The W&F Mechanik is a typical, Swiss medium company with 20 employees. The Basel domain, where Therwil is located, is of significant economic importance, as it is also the home of companies such as Endress+Hauser, Novartis, Hoffmann-La-Roche and Ricola.

The company W&F Mechanik was created in February 1980 by the actual owners Werner Wüst and Edi Flury. The objective of the company was to create a service-oriented business, where all sorts of things would be manufactured: from single, mechnical parts to complete assembly or entire machines serving special purposes. This ambitious objective can only be reached with expert staff, high-performing machines and efficient programming. The W&F Mechanik company does have competent, highly trained staff at hand: a lot of employees have been there for quite a long time and can therefore bring their Know-How on a daily basis in the operation of the buiness. The clients of the company are in the technical medical area, in the semi conductor, machine manufacturing or armor industry.

Efficacy and machinery are key

While client expectations and the complexity of the components are constatly growing, short-term, and affordable manufacturing is also a key factor to sucess.

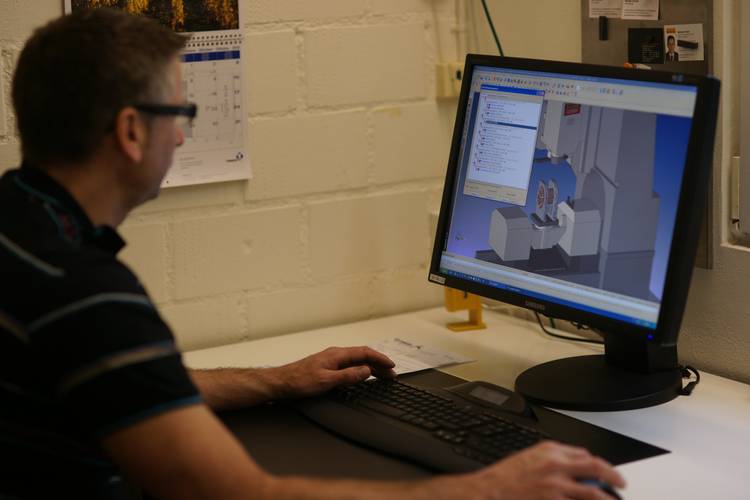

That's precisely why W&F Mechanik acquired a CNC-machine: after the acquisition of a 5 axes CNC machine, the company was soon faced with the necessity of having an efficient programming for the upcoming machine kinematics. Parallel to the machine evaluation, they searched for an integrated solution, together with the machine operators and programmers. The CAM system must take into consideration all machine kinematics as programming will not be made on the machine directly in the future. Similarily, the CAM system needs to be able to perform a collision test for all the components used on the machine. The range of possible CAM system rapidly got smaller, as it needed to be able to offer 5 axes simultaneous data treatment, together with the integration of MAZAK Integrex Programming into the CAM system. In addition, as W&F Mechanik manufactures not only single parts, but also complete assemblies and machine for special purposes, an integrated mature CAD functionality to the CAM system would certainly be a plus.

Very stable, while highly dynamic

The decision was finally made to acquire the machine QUASER UX500dyn, from the swiss importer of QUASER, RIMA AG, based in Widnau. The machine demonstrates an outstanding stability, while being highly dynamic with the round axes in the field of 5 axes simulaneity on the torque motors. The unbeatable price/quality ratio was also a key factor in the acquisition.

Shortly before the acquisition, the owners Wüst and Flury were able to assess the high performance of the machine at the Rima AG showroom.The company CADAM Solutions AG, Value Added Reseller of the TopSolid product range of Missler Software and CAD-CAM partner of RIMA AG, programmed and manufactured middle-sized busts ("Carmen") with combined data processings, from 2,5D to 5 axes simultaneous treatment with the W&F Mechanik machine.

Post-processor and Know-How of the Value Added Resellers

As the decision about choosing a CAM system was not made yet, the benefits of the TopSolid product range were also debated. Early in the discussions, it became obvious that not only the software, but also post-processors and the Know-How of the Resellers play an important role in the integration of the software and the machine. W&F Mechanik also expressed the necessity for the existing machinery to be connected to the network. The extensive practical experience of CADAM Solutions using TopSolid, together with experience on QUASER- machines and machining led towards CADAM Solutions and TopSolid. CADAM Solutions was also able to support the newly acquired customer in the field of clamping systems, tooling and tool holding thanks to the extensive knowledge of the CADAM staff on the matter. The team particularily kept a careful eye on applicability and adequacy of upcoming contracts, as well as new projects. 3 other systems also made it in the final selection list, next to TopSolid. However, soon after product demonstrations of competitor, the benefits of TopSolid became obvious. The machine programmers were convinced by TopSolid thanks to its visually appealing system, the integrated CAD-CAM, the user-friendliness and the clear, intuitive handling of the software.

Customised software developements

Following the machine delivery and activation, the first 5 axes components were programmed and manufactured, with the support of the CADAM Solutions team. While being trained on the machine, the W&F Mechanik employees also received basic training on TopSolid'Design and TopSolid'CAM in Rotkreuz. In addition, CADAM Solutions also handled the hardware side of connecting the machines and started developing a simple DNC Solution, cadamDNC, which went perfectly together with TopSolid and which took over the complete data maintainance via data bank.

A further software development by CADAM Solutions took place with cadamTOOL. In the past, the TopSolid user had to inquire several times about data base or templates for TopSolid's own tooling data base TopTool. Therefore, CADAM Solutions looked for a user friendly solution and developed its own cadamTOOL for this purpose. CadamTOOL simplifies the gathering of tools with more than 80 parametered 3D models and more than 2500 tooling data records from renowed tool manufacturers (more infos: www.cadam-solutions.ch). This cadamTOOL can be acquired by any TopSolid user; while any CADAM Solutions AG client can use it for free. Denis Wioland, CAM-Porgrammer of W&G Mechanik explains: " data processing with cadamDNC and the realistic tools from cadamTOOL facilitates an efficient and easy use."

Customer satisfaction and positive lookout on the future

"We had a first positive impression of TopSolid, which was later confirmed. We are very satistifed with our choice and would choose TopSolid again at any time", states Denis Wioland, a TopSolid programmer for W&F Mechanik. Thanks to TopSolid, error rates with this system, as opposed to manual programming, have reduced drastically. It opened new possibilities for parts manufacturing, which could have not been possible without a CAM-system, and allowed, depending on which part, time savings between 30 and 50%. Concerning the Value Added Resellers CADAM Solutions AG, the service delivered and the client relationship are particularily appreciated by the client. The owner Werner Wüst and the TopSolid programmer Denis Wioland both agree:

"thanks to the experience of the CADAM Solutions staff, all our technical requests were treated rapidly and we received strong, relevant support- this is typically the type of customer service you want."

The perspectives for the future are a combination of carefulness and optimism. Werner Wüst underlines that it's probably going to take 1 to 2 years, if not more, until the economy recovers from the severe financial crisis. Despite this, contracts and sales have gone up, and a higher workload for the small and medium businesses in Switzerland is easily detectable. With the conviction that this upgoing trend is going to last, the future is definitly looking up!

Meer informatie nodig

EEN VRAAG OVER ONZE PRODUCTEN OF OPLOSSINGEN?

Vind uw dichtstbijzijnde verkooppuntContacteer onsVraag een offerte aan