14 april 2020

Tailor-made machines for flexible materials. CNM Process, a small company based in the Drôme region of France, calls on TopSolid'Design to design its machines that process technical textiles, foam, felt, rubber, composites, etc. With significant time saving and very strict management.

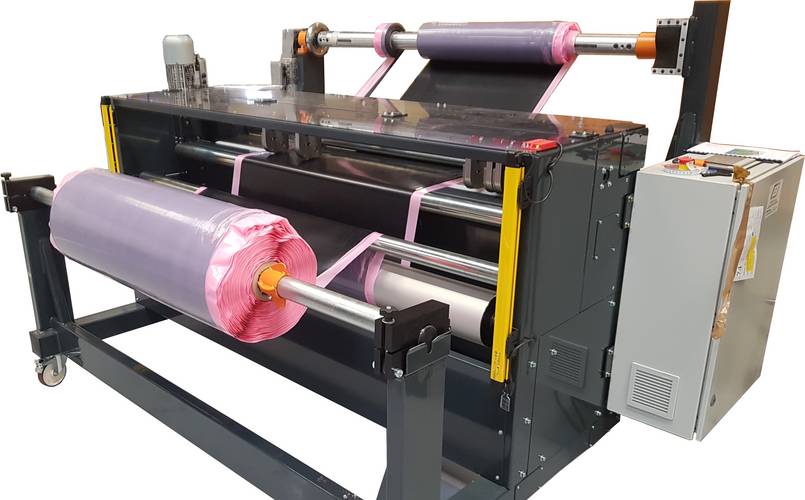

Created in 2013 by Christian Nouyrigat in Saint-Donat-sur-l'Herbasse, a small town of 4,500 inhabitants located in the Drôme region between Romans-sur-Isère and Tain-l'Hermitage, CNM Process designs and manufactures non-standard machines. "We provide tailor-made solutions for the processing of flexible materials, such as technical textiles, foam, felt, rubber, composites, plastic films, etc.", says the entrepreneur. Rewinders/slitters, rotary cutting machines, winders/unwinders, laminating installations, gluing systems, consumables (blades and conveyors for cutting tables), etc. The company, which employs seven people, including four specialists in the design office, offers a wide range of equipment in which users can easily find the right shoe that fits. Upon request and according to the needs of the user, special equipment can be manufactured. "Adapted to the processing of these delicate materials to operate, the cutting technology that we have developed combines versatility with simplicity of use and ease of adjustment, performances that are rare on the market," said the CNM manager. The digital control of some machines ensures complete and automated management of the work cycle by recording parameters in the production recipes. Other equipment has a touchscreen display with recipe functions that allows complete control of the machine and the processing cycles. "In addition to our productions, we distribute gluing robots in close collaboration with our partner," explains Christian Nouyrigat. "From several years of experience and in-house development, a robot automates the gluing operations by removing all programming constraints.”

A true design solution

Equipped with a vision system coupled with a CAD/CAM (computer-aided design and manufacturing) software, the latter ensures the automatic generation of tool paths. "All of these solutions are highly sought-after by packaging, conveyor belts, seals and technical textiles manufacturers that use the raw materials supplied by 3M," said Christian Nouyrigat. A manufacturing process that has become more complex over the years. "We used to use mechanical CAD software in the design office, but it no longer suited our needs," says the specialist. In 2016, after an in-depth market study, he decided to be equipped with the TopSolid’Design software. "At the start of my research, I was rather inclined to choose a competing solution that I was even about to buy", explains Christian Nouyrigat. "The presentation of the capabilities of TopSolid’Design V7 by the TOPSOLID SAS application engineer and the tests of this solution carried out with his assistance made me change my mind." As a result, this small business acquires two permanent licenses and one license on loan of TopSolid'Design V7. "A powerful CAD solution with its on-the-fly configuration capabilities, this CAD software is capable of taking into account the variety and complexity of our equipment", says Christian Nouyrigat. "With a very beneficial time-saving in terms of design thanks to the automation of tasks. In addition, its integrated PDM is of great help to facilitate the management and scheduling of manufacturing operations. For example, when it comes to re-editing a drawing, all the information is immediately updated, which avoids many setbacks. Being able to simply rename files is also a big plus for TopSolid’Design, as this function saves more than 50% in terms of time." According to the entrepreneur, you must also be very careful when choosing a CAD/CAM solution. "We should attach great importance to our suppliers and their ability to respond quickly to our challenges," advises Christian Nouyrigat. "And this is especially true when dealing with the editor, as we did with TOPSOLID SAS. The ability to support young companies like ours is an essential asset." This successful experience encourages CNM Process to consider new projects, such as the upcoming implementation of TopSolid'Cam software to digitize the entire design-manufacturing chain.

Key points of TopSolid'Design V7

- The design automations ensure considerable time savings.

- The design is intuitive and adapts to the designers' approaches.

- The integrated PDM facilitates the management of manufacturing operations and eliminates errors.

Christian Nouyrigat's opinion: "TopSolid’Design V7 allows us to go faster and better in the design of our specific solutions for the machining of soft materials. The high quality technical support provided by TOPSOLID SAS specialists is extremely responsive and adapted to our needs."

Meer informatie nodig

EEN VRAAG OVER ONZE PRODUCTEN OF OPLOSSINGEN?

Vind uw dichtstbijzijnde verkooppuntContacteer onsVraag een offerte aan