9 november 2015

Reactivity and productivity are the main benefits provided by TopSolid’Design software to this microenterprise specialised in the production and maintenance of complex production lines and units.

The company may be small, but it has big ideas. Located in the town of Montauville, near Pont-à-Mousson in the Meurthe-et-Moselle department, ABI (Ateliers du Bâtiment et de l’Industrie - "Building and industry workshops") pulls out all the stops to propose the best possible solutions to its customers. ABI is a small set-up employing six versatile specialists, capable of dispatching complex projects with skill and discipline.

The adventure began in 2006 when Jean-Luc Zingerlé, a seasoned industrial maintenance professional, decided to become his own boss by founding an industrial maintenance company. "At first," the entrepreneur explains, "ABI focused on local projects, repairing machines and doing jobs on industrial infrastructures." The sheer professionalism of this microenterprise would quickly pay off, and bigger contracts – mainly in the agri-food industry – would soon come its way. "Our first jobs," the specialist goes on to say, "concerned changes to the layout or reconditioning of production lines, modifications and reconditioning of storage structures." Then, the conveyors manufacturer, Flexlink, asked ABI to become a certified installer of its conveyor lines. The Swedish manufacturer's design centre studied the production lines and prepared the layouts, while it was ABI's job to come on site to implement the physical set-up and fine-tuning operations. The result of this was that it became a company with international reach, installing Flexlink production lines for the BEL cheese group in Canada, the USA, Algeria, Turkey, etc.

In building up this experience and winning the trust of customers that include some of the biggest names in agri-food and industry, ABI would find itself on an upward curve, boosted by the use of powerful design tools provided by Missler Software. "It was by word of mouth that we found out about the existence of TopSolid’Design", says Jean-Luc Zingerlé.

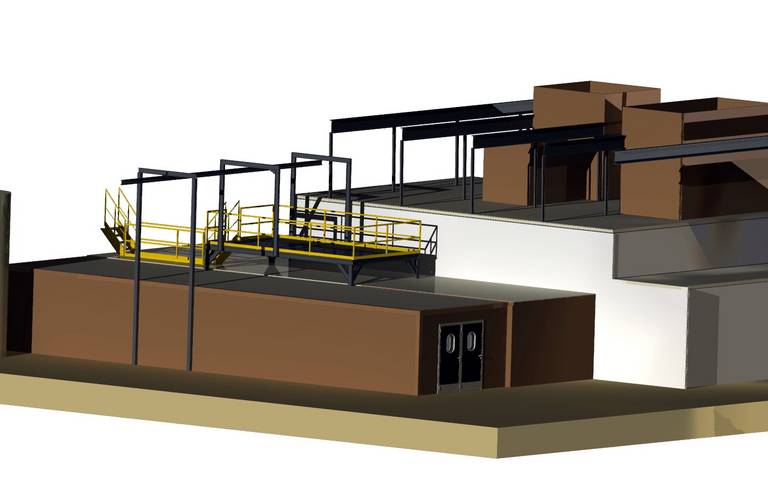

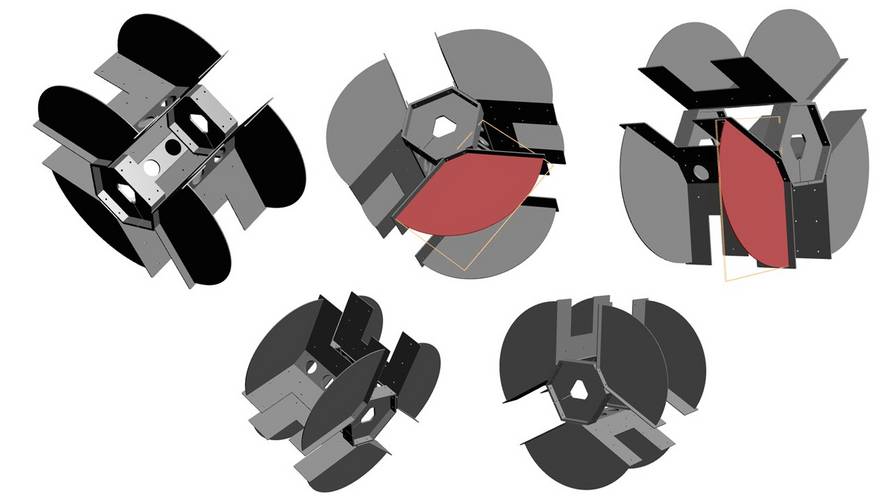

Initially, TopSolid’Design produced the plans of the parts to be manufactured for machine maintenance. Yet the extent of its usefulness really came to light with the arrival of complex contracts. "3D modelling and the powerful configuration functions of the software have changed our lives and our customers' lives," the expert observes. "Our customers are able to analyse their future installations from every angle, detecting any possible problems in advance, before transitioning to project production. For us, this is a vital safety mechanism, as it would be for any microenterprise without a maintenance department or project manager." So now there are no more on-site installations without due preparation. The solutions are studied and prepared in the workshop, using shop-test assemblies if necessary. The slightest imperfections are rapidly detected, thereby facilitating fine-tuning and integration, and therefore, by the same token, customer acceptance testing, with minimum sign-off reservations. With the CEO swearing by the notion of autonomy, ABI controls the design and manufacturing of most of the components, while TopSolid’Design takes care of the modelling. All that then remains is to manufacture the parts in their own boiler shops and machining workshops or, if necessary, call upon their subcontractors. "Being able to provide our suppliers and technicians with reliable 3D plans has significantly improved our reactivity and the quality of our services," says Jean-Luc Zingerlé. "This represents a major financial gain, considering the manufacturing volumes involved."

Be that as it may, the company has not rested on its laurels. Faced with the far more technically arduous production of projects for the installation and manufacturing of roof frames, the company decided to install the finite elements calculation module of TopSolid’Design. "This was indispensable", states the specialist, "for avoiding design errors, adapting the solutions as accurately as possible, ensuring best-price estimates, reassuring our customers and reassuring ourselves." Being sure of the right calibration (mechanical and financial), being able to provide the right calculation elements, enabling surprise-free acceptance and sign off by the various inspection bodies for our installations: these are all benefits that TopSolid offers.

Equipped in this way and bolstered by its advanced skills in CAD (computer-aided design), ABI has been able to ramp up its business to take on complete manufacturing projects for production installations, such as cold storage rooms, or one of its latest projects: the turnkey installation of a banana packaging plant in Guadeloupe.

The benefits of TopSolid’Design are not, however, limited to the technical design process. The software has also opened up many commercial pathways. Practically all the projects are modelled in 3D, sometimes dynamically, and sent to customers along with the estimate. The simple fact of being able to view the project enables customers to check that the solution corresponds to their actual needs, and that it complies with the technical brief. This preparatory work boosts the acceptance rate for the estimates, which is well above the average. There is certainly no shortage of projects on the books at ABI, and the company is looking to install presently, depending on how orders develop, a full-fledged mechanics workshop, with an automated paint line, precision milling and turning, and high-capacity bending.

TopSolid’Design: the strong points

- 3D modelling that allows customers to view and analyse their project in detail

- Finite elements calculation to avoid errors, adapt solutions accordingly and cost them accurately

- Powerful configuration functions that improve reactivity and productivity

Meer informatie nodig

EEN VRAAG OVER ONZE PRODUCTEN OF OPLOSSINGEN?

Vind uw dichtstbijzijnde verkooppuntContacteer onsVraag een offerte aan