4 September 2019

TOPSOLID, France’s leading CAD/CAM software publisher for the mechanical industry, will be at the EMO show in Hannover, Germany, from September 16 to 21 – Hall 9 Stand A04.

TOPSOLID chose this major international event, the world’s n°1 trade show for the metalworking industry, for players from the world of manufacturing to present the new features of its TopSolid’Cam software supported on the local market by its resellers Moldtech, AdeQuate Solutions and West.

The performance of the software has improved constantly since the latest generation of TopSolid was released, reducing average production times by 30% to 40%.

Come and see the power of the TopSolid solutions on the stand. Hall 9, Stand A04.

Here is a quick preview of the main new features.

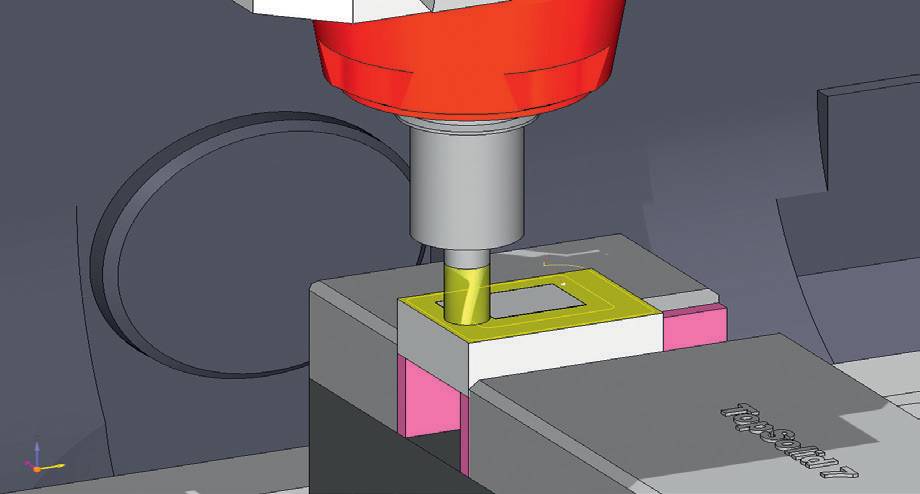

NEW ROLL-IN APPROACH STRATEGY

Increase the lifetime of your tools with the new roll-in approach strategy!

This new approach strategy allows for soft entries into the material. In this way, the lifetime of cutting tools is extended by avoiding shocks when entering the material.

AN EVEN MORE EFFICIENT ANTICOLLISION ENGINE

Save time with the new high-performance collision analysis mode!

A new high-performance collision analysis mode has been built into drilling operations, 2D and 3D milling operations. This analysis controls collisions between the finished part and the complete tool. Its rapid execution makes it very useful when predicting collisions, even in complex machining strategies.

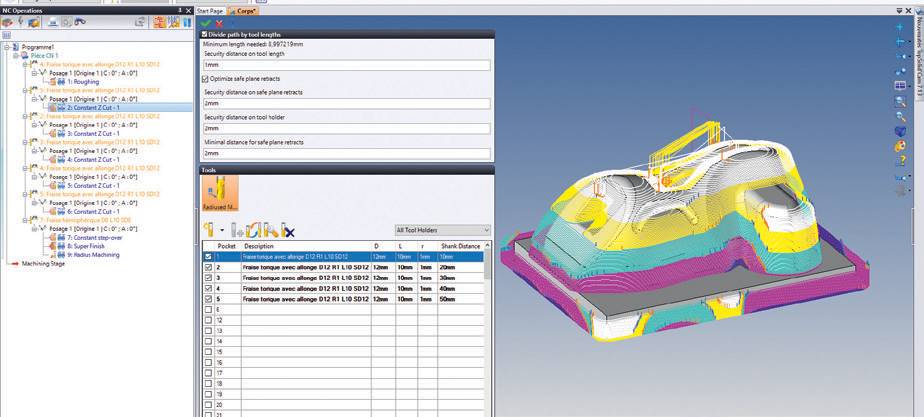

TOOLPATHS ACCORDING TO THE CAPACITY OF YOUR TOOLS

Stop wasting your time. TopSolid’Cam can now do the job for you automatically!

The option to divide the toolpath into usable tool lengths automatically divides a machining operation into “n” machining operations according to a selected list of tools with different tool lengths. Each machining zone is determined according to the length of the tool and the diameter of its attachment.

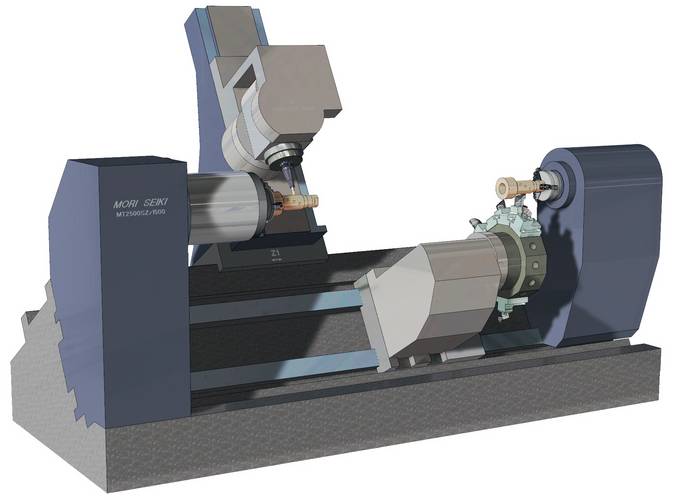

EASIER PART TRANSFER AND PULLING IN MILL-TURNING

Easier programming, with dedicated features that are very easy to use!

Three new part movements have been created to facilitate part transfers and to allow parts to be pulled.

• Approach to hold part : this option automates and facilitates the approach of the sub spindle to the main spindle in order to hold the part.

• Part pulling : this option now enables the part to be pulled with the sub spindle.

• Part transfer : this option automates and facilitates part transfers from the main spindle to the sub spindle.

COMPLETE AUTOMATION OF YOUR MACHINING PROCEDURE

Take the automation of your machining programs to an even higher level!

A new drilling cycles and cylinders stacking feature has been added to the general milling/turning methods. You can now create and save complete jobs list that can be automatically applied to your new parts.

Necesito más información

UNA PREGUNTA SOBRE NUESTROS

PRODUCTOS O SOLUCIONES?

Encuentre su punto de venta más cercano Contacte con nosotros Obtener un presupuesto