3 September 2010

High-precision machining of oversize heavyweight parts.

CAM machining in 3D for job order production

Leipert Maschinenbau GmbH has its headquarters in Kraichtal-Landshausen, Germany. The company specializes in high-precision machining of oversize heavyweight parts. Although most parts are still designed in 2D, job order manufacturer Leipert uses Missler Software Software’s TopSolid’Cam 3D CAD / CAM solution for CAM programming, the objective being to increase overall productivity and the quality of CNC programs.

Leipert was founded by Albert Leipert in 1956 and started off with the assembly and maintenance of agricultural equipment. By establishing a corporate turning and milling shop, Leipert laid the foundation stone for job order production. Since the seventies, Leipert has been working for huge international manufacturers of squeezing machines, turbines, machine tools, and other oversize parts. According to Junior Manager Jeroen van de Ven, the company has maintained long-time partnerships with many customers. “High quality and adherence to delivery dates form the basis for customer satisfaction.”

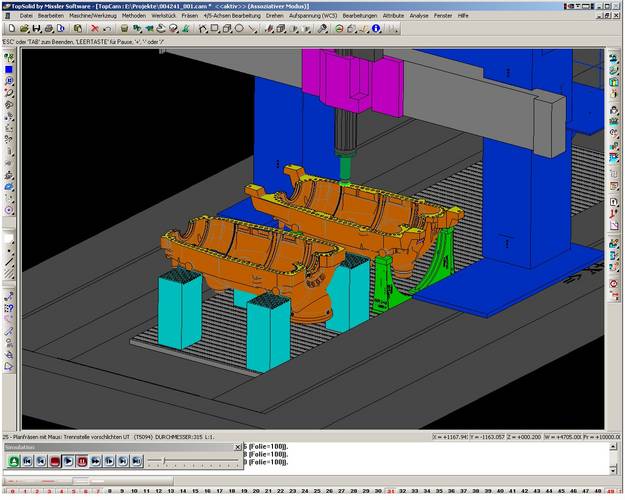

Currently, Leipert has approx. 70 qualified employees and offers its customers state-of-the-art machinery for milling or turning of heavyweight parts accurate to one hundredth of a millimeter. The portal machining center Waldrich PMC 6500 can process parts with dimensions of up to 20x6.3x4.5 meters and weighing up to 110 tons. Leipert recently purchased one Waldrich VTF 8000 vertical turret boring and milling center for machining parts with up to 8 meters in diameter, 5 meters in height and weighing 200 tons.

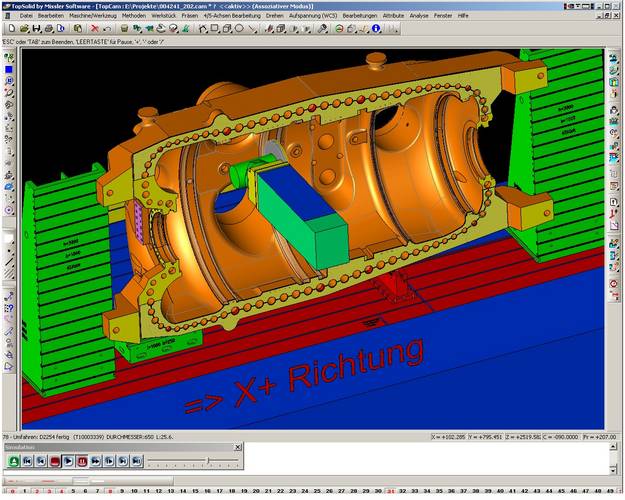

Accurate CNC programming is a prerequisite for the efficient use of these extraordinary machines. Once the part is fixed on the machine table, corrections become time-consuming and expensive. The increasing complexity of parts to be machined entail a higher risk of collisions, which are easily overlooked in traditional CAM programming using an editor and 2D drawings. Being a job order manufacturer, Leipert cannot afford errors because all parts to be machined are single parts. For this reason, the company decided to migrate to 3D programming.

“Parts and thus machining become increasingly complex,” explains Gerd Reich, CAM Programming Manager. “At the same time, machining centers become ever more sophisticated. Machining possibilities have drastically increased due to a greater variety of heads and tool holders. By using the 3D programming system, machining workflows involving part, tool, and machine can be reliably simulated which in turn ensures flawless machining.”

Collisions in check

Next to flexibility and adaptability, the solution’s powerful functions for collision control were among the decisive points to decide in favor of Missler Software’s TopSolid’Cam software, which Leipert has been using since the beginning of last year. TopSolid’Cam was compared with other CAM solutions such as Tebis and UGS before making the final decision. Yet another important criterion was the ease of use which greatly facilitated the transition from 2D to 3D.

TopSolid’Cam is a CAM system for simultaneous milling with 2 to 5 axes that is based on the parametric and associative TopSolid volume modeler. Therefore, features such as holes, pockets and slots can be assessed automatically during the generation of CNC programs. Existing programs are updated with a mere mouse click whenever changes are performed on the model. Among the strengths of the software is the possibility to reuse existing machining procedures for similar parts. The latest version offers functions for optimizing the increment size between machining steps while maintaining maximum scallop height to further speed up machining.

Leipert currently uses TopSolid on five networked PC workstations running under Windows XP. One of these workstations is used for 3D part modeling, the other four serve to generate CNC programs. Missler Software sales partner WeSt conducted a three-day user training for the CAD / CAM module. According to Reich, all users were then able to independently work with the new software. “We cannot afford extensive training because manufacturing must be up and running all day.” WeSt also took over the programming of initial post-processors. Users received a special training in programming additional post-processors independently and in adapting these to the requirements of the corporate machinery.

To be able to use the collision control functions, machines and tools first needed to be mapped in the software. “Because we had no machine models we included the machines’ measurements along with all details that are important for collision control, and modeled the machines on this basis. We also established tool libraries ourselves,” says Reich. “This took quite awhile, but we were able to use the system efficiently after 6 months. We created machining centers including aggregates and kinematics. These centers are adapted to current requirements if necessary.”

Open data import

Since many of Leipert’s customers still design in 2D, users frequently need to model the parts before CNC programs can be generated in 3D. As a general rule, customers provide 2D data in DXF format that can be imported in TopSolid to rapidly create models on the basis of part contours. “Our design processes are machining-oriented, i.e. we focus on every detail that we need for machining and/or collision control,” says Reich.

In the past, high data volumes of machine, tool and part models in 3D had been a huge problem. In the current TopSolid version, however, data volumes are reduced because the software contains enhanced memory management and an incremental graphics function, i.e. when altering shaded models, only facets of changed surfaces need to be recalculated instead of the entire model.

Nevertheless, part modeling represents additional effort for the company. However, this effort is reduced if customers migrate to 3D design. Thanks to the openness of TopSolid, 3D data can be imported in high quality from all common CAD systems in original format or in standard formats such as IGES or STEP. The software features a bidirectional CATIA interface and can read data from Parasolid-based systems without converting them because both systems use the same modeling kernel. Reich estimates that the share of 3D data received from customers is currently at 10%.

Not much need for automation

Part modeling with TopSolid is advantageous in comparison to the import of 3D data: for certain operations, predefined features can be used that the CAM module automatically converts into corresponding machining cycles. However, Leipert engineers can only use these automatic functions to a certain extent because parts are usually single parts.

When selecting the optimum milling strategy, users—who all have a manufacturing background—rely on their manufacturing expertise instead of on the software. To facilitate work for machine operators, standardized procedures have been developed for machining.. “We make sure that certain milling operations are always programmed alike. A contour is approached in a certain way so that the machine operator immediately recognizes which process he should follow.” explains Reich.

“One of the essential benefits of TopSolid’Cam is the possibility to program highly complex machining steps. This had not been feasible with the old 2D solution. With many parts it is not obvious at first sight that they need to be machined with 5 axes,” says Reich. “We can manufacture parts with draft holes in 3D or helical slots. This had not been possible before. Therefore, we have become more versatile.”

Part machining can be simulated on the computer. Visual collision control allows CAM programmers to eliminate possible errors prior to machining. Residual material is no longer overlooked because the system recognizes residue after each machining step. The software then proposes ways to remove this material. Users at Leipert mostly use virtual collision control because the exact computation would take too much time with the current hardware. In addition, fixtures and clamps would need to be placed, accurate to a millimeter, as simulated on the computer—which is difficult for heavyweight parts.

Increased process reliability

Automatic recognition of residual material and visual collision control have reduced the number of errors for complex parts as well as approach errors in the shop. 3D programming adds further convenience by eliminating manual input errors. Higher process reliability substantially contributes to shortened cycle times—although the time needed for program generation has not substantially decreased due to the additional effort for 3D modeling.

“I assume that in the medium-term, we can increase our productivity with TopSolid’Cam by 20 to 30 percent,” comments Junior Manager van de Ven. However, these savings are hard to quantify since current manufacturing projects cannot be exactly compared to old ones. Using 3D for CAM programming also ensures that Leipert gets ever more complex orders from their customers, such as the complete machining of a turbine casing including intermediate assembly. “We have become more competitive and can serve new customers,” says Jeroen van de Ven.

As a case in point, Leipert recently took over the roughing process of a deep-drawing tool for fenders for a renowned automobile manufacturer. Without TopSolid’Cam, the company would not have been able to read freeform surfaces from CATIA and to process these with five axes simultaneously.

Report By Michael Wendenburg, Seville.

Photos by BGC.

Potřebujete více informací

máte OTÁZKu TýKAJÍCÍ SE NAŠich

PRODUKTŮ NEBO ŘEŠENÍ?

Najděte nejbližší prodejní místo Kontaktuje nás Získejte nabídku