1 April 2011

Now more than ever, precision mechanics face the daily challenge of proving that their skills are superior in their trade. CAD/CAM software is expected to offer high performance quickly and easily – with “just one click”. This is what allows programmers to process their customers’ requests with the best possible performance. Moreover, to ensure user-friendliness, the various modules in a software package have to operate according to a common logic. There is one such product on the market.

In April 2000, Alain Laude founded Micro erosion, a company operating in the connector technology market, specifically for the mobile telephone industry. With his extensive knowledge of the field, the company’s founder invested in wire-spark machining tools and began machining parts based on drawings provided in DMX format. He quickly earned a reputation for providing high-quality work under tight deadlines. This ability to ensure fast turnaround was particularly well-suited to Just-In-Time orders. However, in 2001, he lost the market and turned to the manufacture of plastic injection molds and trim dies for the automotive industry. 2004 was another hinge year for the company, as Alain Laude grew weary of the purchase terms imposed in the automotive industry, and the payment terms in particular. It was time to branch into new markets! Showing incredible adaptability, the CEO turned to the military, defense, medical, semi-conductor and medical automation sectors. He also saw a strong demand among customers for engineering which included the involvement of highly-skilled sub-contractors and collaborators. To satisfy this demand, Alain Laude had his own theory: “A percentage of our sales must come from consulting. Moreover, we need to have the highest-performance tools and invest in the most-adapted CAD/CAM software available. In exchange, we ask that our customers provide drawings solely in DMX or DWG format, which allows us to improve the products in excellent time.”

One for all and all for one!

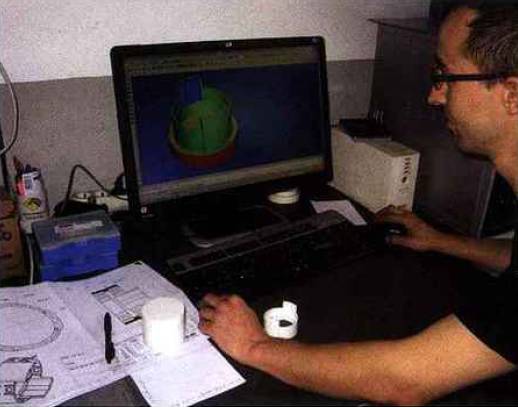

Micro érosion currently has 4 employees, and the operators can run 90% of the company’s production tools. In the workshop, one sees tools from the GF group, Charmilles EDM machines 2030, 4030 and 2050 with the System 3R robot, a Roboform 4000 die-sinking machine, and a Mikron HSM 400 centre with an Erowa automatic pallet changer. Until 2007, part programming was carried out with GOelan equipped with a post processor for the EDM machines and the gateways needed to import customer files. As demand increased in terms of design, reworking and changes to certain parts, the designs needed to be simplified in order to make them less costly. Alain Laude explains, “When a part is broken, it is more cost-effective to define a portion of it as expendable than to remake the entire part, so we have to create an insert centered on a dovetail, which makes the maintenance easier and less expensive. Similarly, it is more cost-effective to design a part in two pieces rather than as a single piece when the surface conditions in its ducts require polishing. This is especially true given that the vast majority of the parts we machine are made of hardened steel and tungsten carbide. For all of these reasons, in 2007 we invested in the complete TopSolid software package from Missler Software.” For Alain Laude, the aim of this approach was to eliminate any redundant tasks in the drawing, design and machining phases. With TopSolid’Design, TopSolid’Cam, TopSolid’Wire, TopSolid’Electrode and, most recently, TopSolid’Mold, all needs are covered with a single supplier, a common interface and the same philosophy no matter which software and module is being used.

Numerous advantages

We must emphasize that the Missler Software products purchased by Micro érosion represent the only integrated numeric chain on the market. According to the French software developer, TopSolid'Mold is the only solution offering effective end-to-end management of mold making, from the design phase to creation of the 2D profile, with advanced functions for design modifications during the process. TopSolid’Mold is completely associative, all aspects of mold making are covered, using trade-specific vocabulary and offering the main component libraries on the market. Moreover, TopSolid'Mold is a CAD/CAM solution which allows multiple designers to work together on the same design, enabling savings in terms of time and money. At a later stage, control, parting surface, insert and machining process functions are easy to use in TopSolid'Cam. Finally, TopSolid'Electrode is a perfect supplement to TopSolid'Cam, allowing electrodes to be created on non-millable parts in a single environment and with associative organization. Alain Laude praises in TopSolid, first and foremost, the fully integrated package and associativity between the various modules that immediately won his approval. He also speaks highly of the excellent communication and responsiveness of Missler Software’s sales staff, technicians and technical sales representatives. In addition, he acknowledges how the product is upgraded, to always be “at its best”! The CEO of Micro érosion explains, “We have to stress the excellent value for money of our investment, and the particularly smooth familiarization phase. We adapted very easily to the TopSolid modules. The fact that the same icons appear in the various modules made the product very easy to ‘sell’ to the workshop. Missler Software also agreed to develop a post processor for the Charmilles 2050 EDM machine, which has highly specific functions. Lastly, we have greatly appreciated the software developer’s reliability, who provides us the same quality of service he ensures for key accounts.”

A job well done

During several visits to TopSolid customers, the magazine “Machines Production” has seen examples of Missler Software’s ability to adapt to the real needs of its software users. From the design phase to production, through its integrated modules, TopSolid speaks the language of mechanical manufacturing. Users focus on their core business and TopSolid calculates how to allow the user create his parts. Moreover, user safety is ensured thanks to real-time collision control and raw part management.

Need more information